ART&DESIGN: Inside Ronin Motorworks

/

Inside Ronin Motorworks

Denver, CO

Ronin Motorworks, creators of the "47 Ronin" concept bikes, announced at the end of September that their story had reached it's end. The brainchild of a few Magpul engineers began back in 2009 after Harley shed itself of Buell and was offering up the rest of it's inventory. The team set out to design a custom platform built off Buell's 1125R. Production of the 47 bikes, each appointed a Samurai name from the Japanese folklore, has seemingly ceased. According to the website 19 of the 47 bikes are still available, ranging from $38,000 - $75,000.

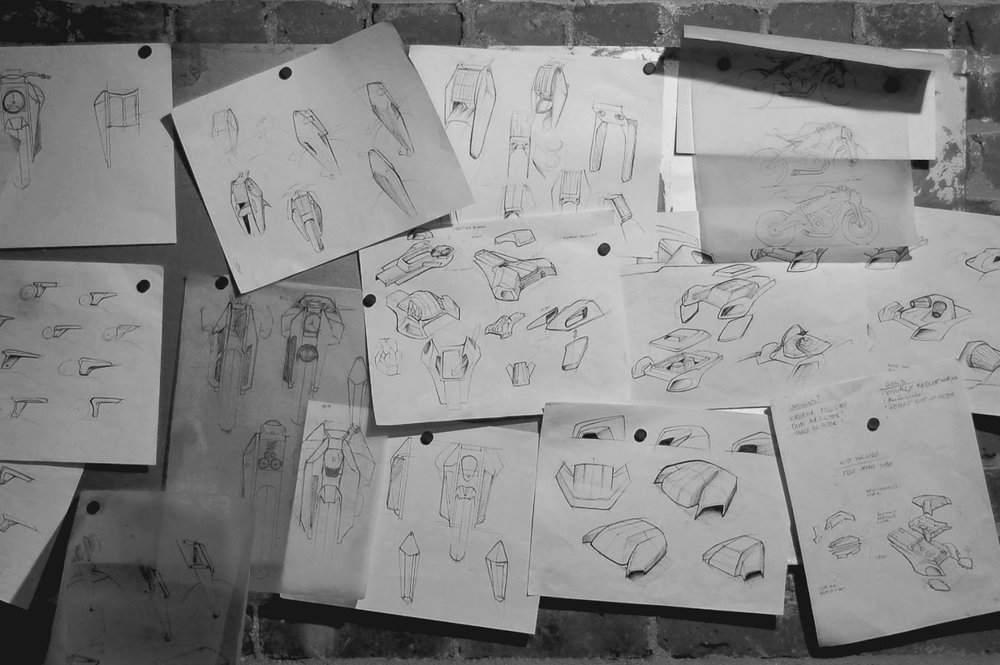

Back in February 2015 I had the chance to tour their shop in Denver. Shane, one of the designers, lead me around their lofted design studio and through the production floor where the bikes were being worked on. There were original sketches on the wall, prototype samples on the tables and clay models from their R&D days. I took a lot of photos with the intention of getting it all up on the blog and somehow it fell to the wayside. So, here's that photo set and what I can remember from that day. Although it's sad to hear the doors are closing, it was a storybook tale from the beginning and it's fulfilling to know they've completed their journey.

Here's the original short film from 2014 that started it all.

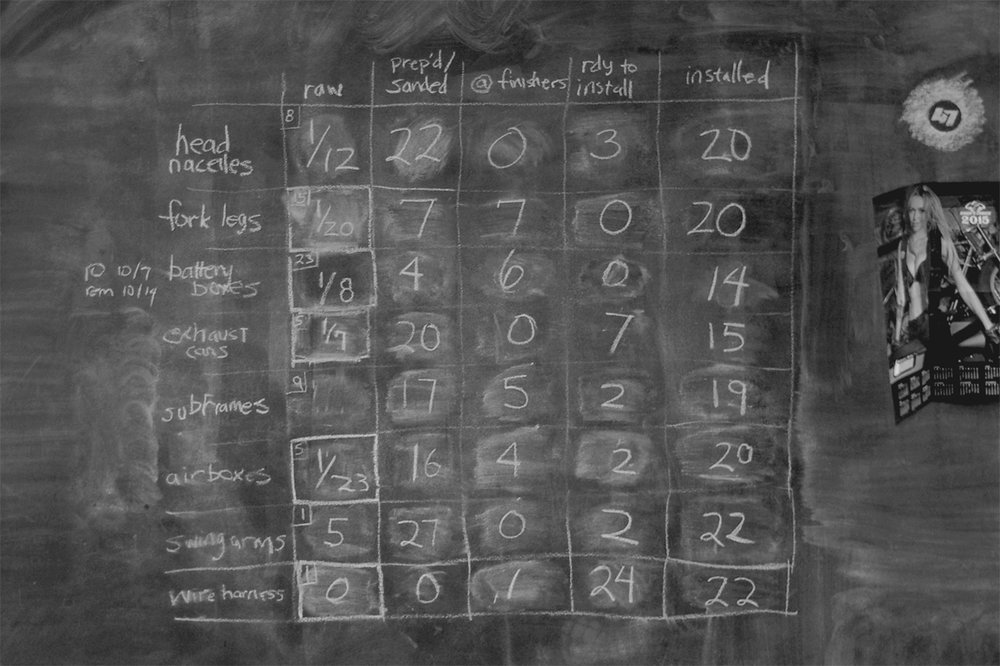

Each frame is stripped of it's nonessential features, brought down to raw aluminum and recoated per it's colorway.

There are a handful of original aluminum castings on the Ronin's, including the front fork assembly, handlebars, and foot controls. The casting finish is too raw straight from the mold so each piece is hand finished to remove all surface imperfections.

A room full of Buell engines and the original prototype bike.

Minor modifications are made to each motor to prevent a few known issues with the 1125 powerplant.

A prototype clay model of the front end is leaning against the wall in the design studio. These type of models are built to view the design in the real world before giving the manufacturing "go-ahead." It's amazing how different a design can look when you're able to see it in front of you instead of on a screen. Clay is used because it allows both additive and subtraction modifications to be easily made. After the model is finessed the clay is 3D scanned and CAD geometry is built around the data points. That CAD is what get's sent to the manufacturer.

And you thought your $38K only got you a kickass ninja bike? Nope! Turns out Ronin squeezed some of that awesome into a few accessory products as well. Here's a range of bottle opener prototypes the design team went through before settling on the long handled with bamboo inlay.

Each bottle opener is scribed with it's Samurai name and number. The steel is "case hardened," a process of strengthening the outer layer of metal. It's commonly used on firearms.

...something Magpul knows a bit about.

This, is the crown jewel of accessories. A CNC cut bamboo toolkit, each with, you guessed, it's name and number carved into it. The coin seen here in the clasp is a magnet that interacts with a sprung loaded lock cylinder. To open the box you must remove the coin, flip it over and reinsert it. The magnet's reverse polarity overcomes the sprung lock cylinder and pushes it into the open position. Yea....holy shit.

Inside you'll find a pair of RFID keyfobs and a case hardened multitool. Inlaid within is a set of bits that fit into the chuck at the tool's base. Honestly this would probably be on my mantle with gallery lighting and lasers while a roll-up of Craftsman wrenches is stuffed under the seat.

That's all. I'm glad I finally got this up. It was one of the most inspiring spaces and stories I've had the pleasure of seeing. A big thanks to the Ronin team for their hospitality and contribution to the custom motorcycle field. They've been one of the biggest players in my eyes and I'd like to hope there's a sequel to their story.