2012-2017

Snap-on Innovation Dept.

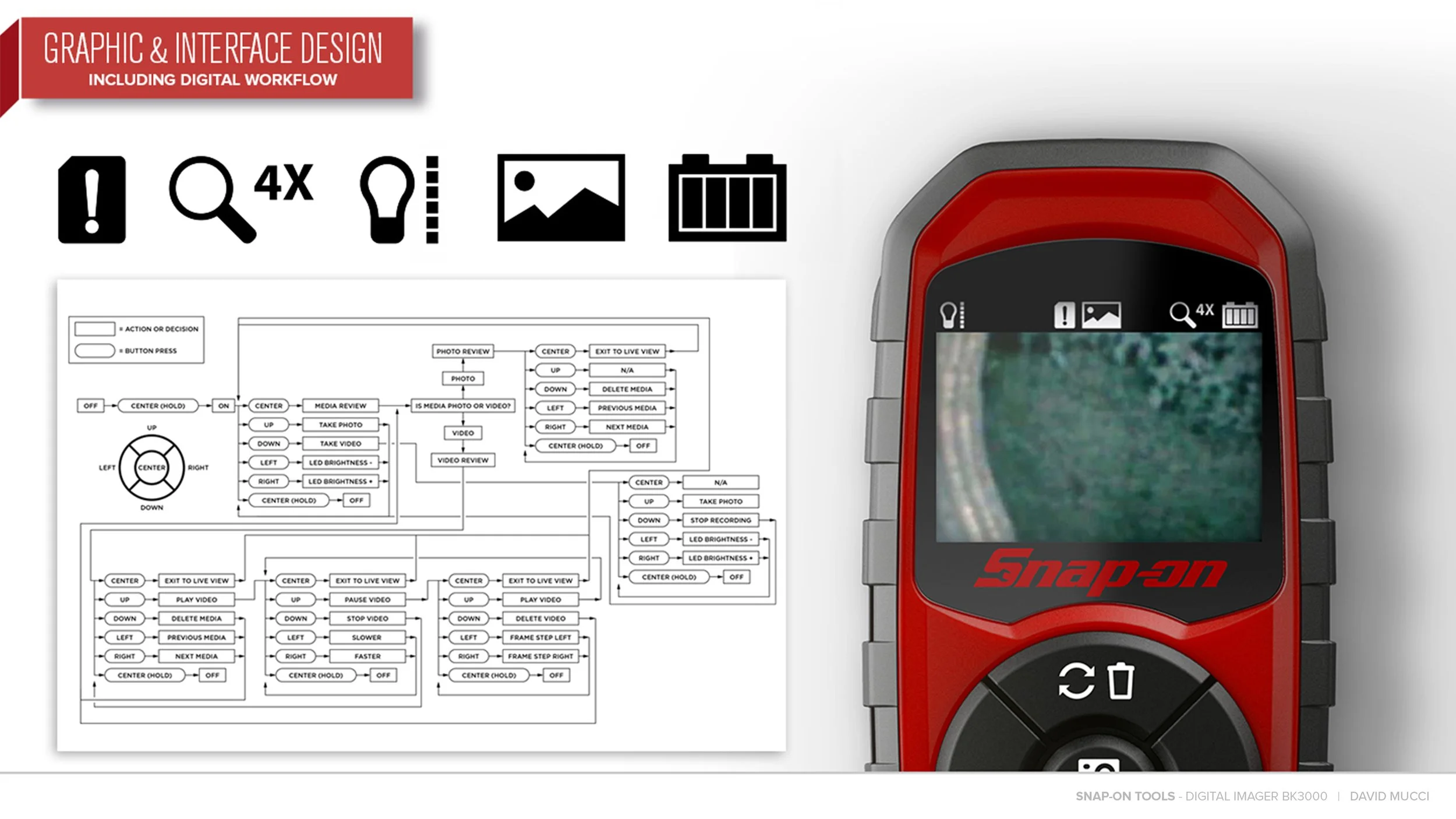

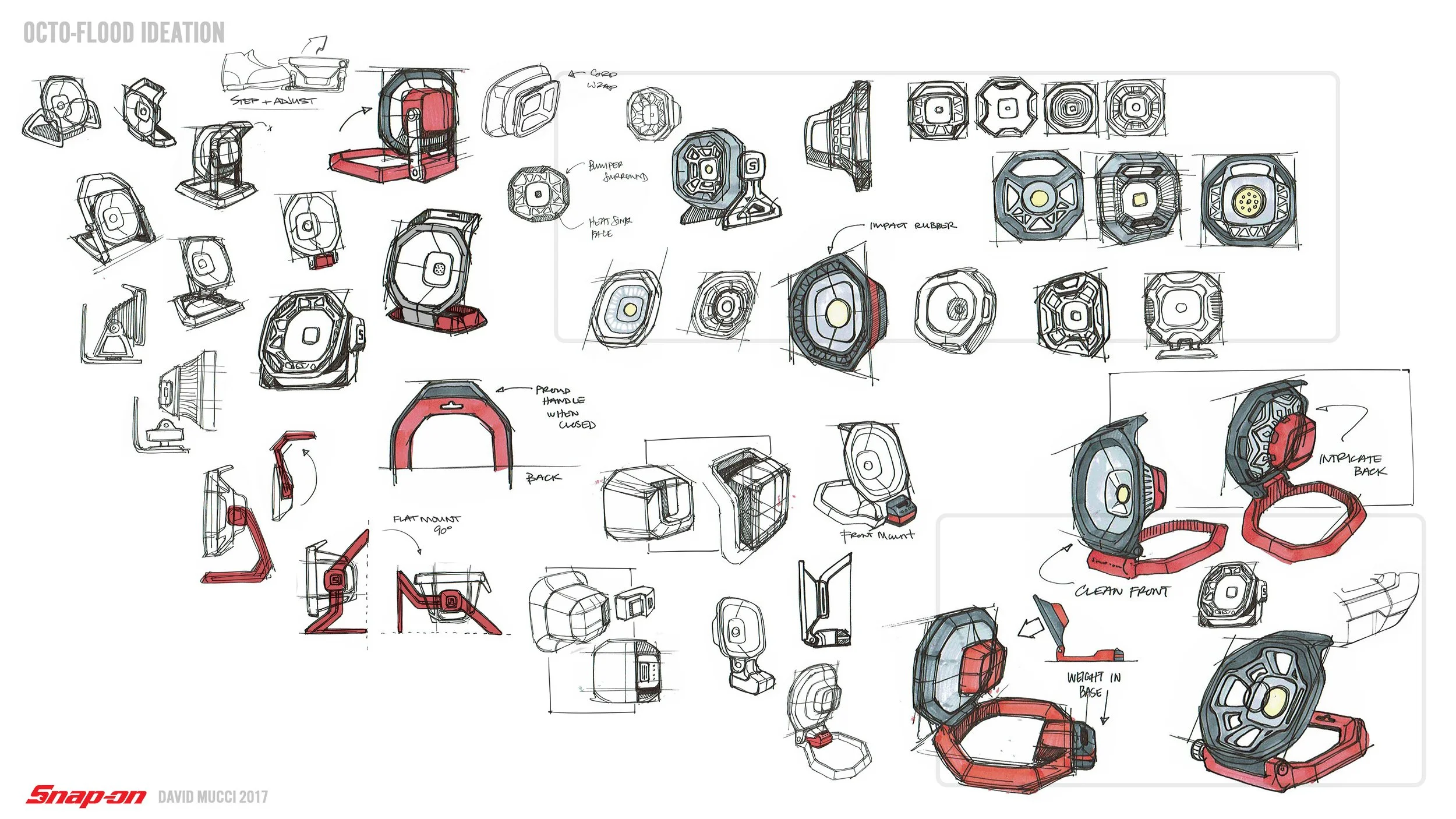

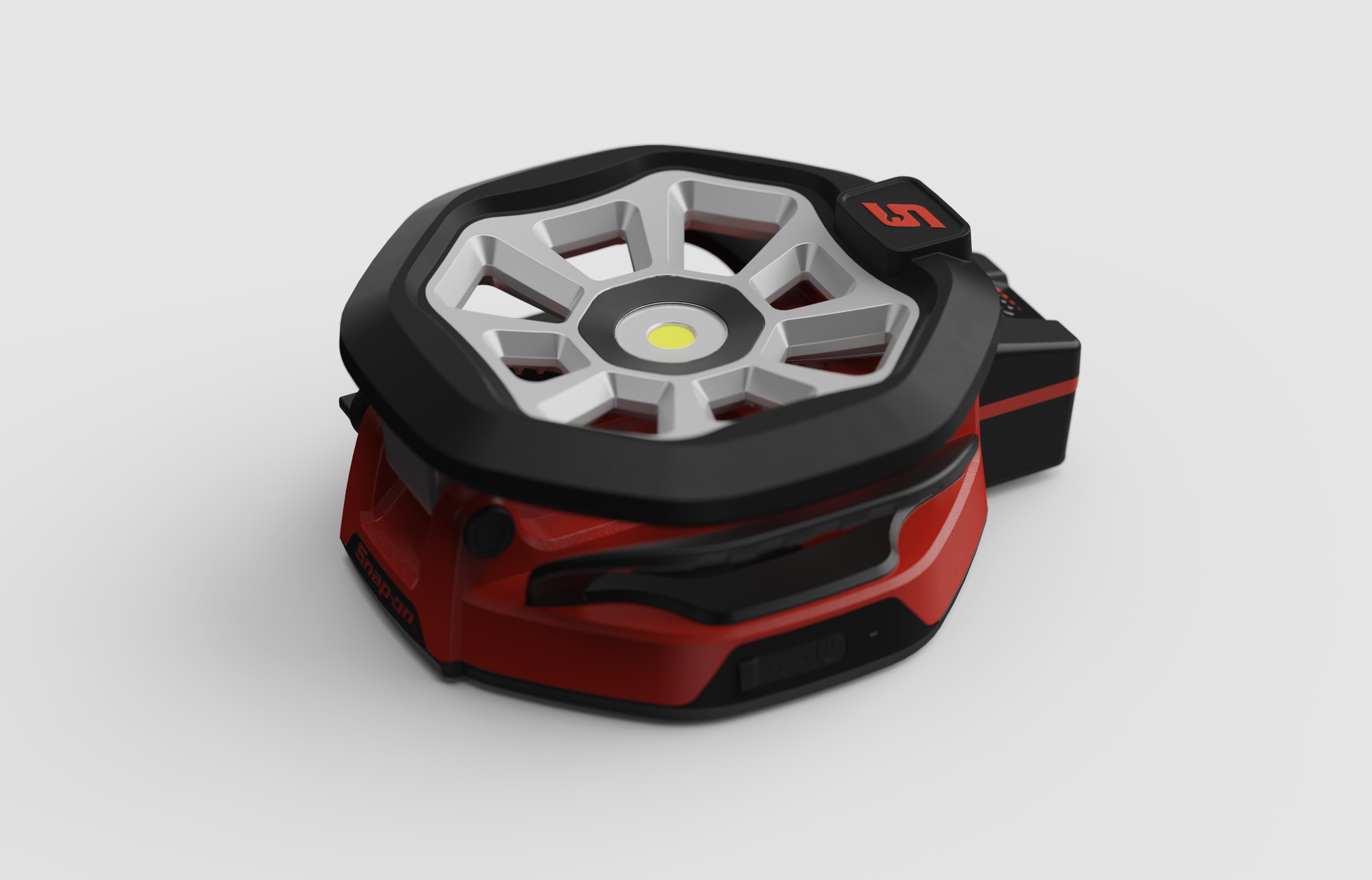

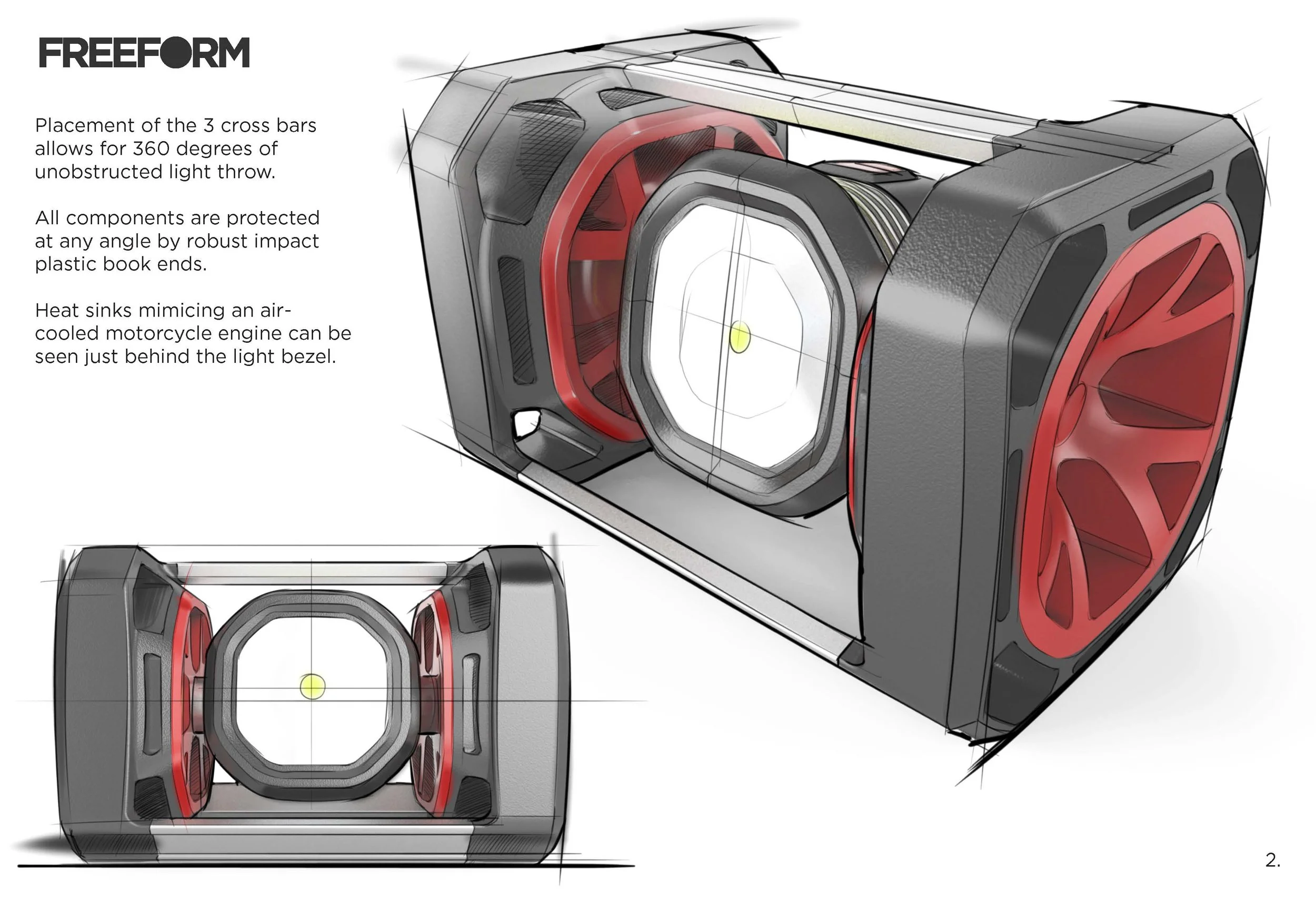

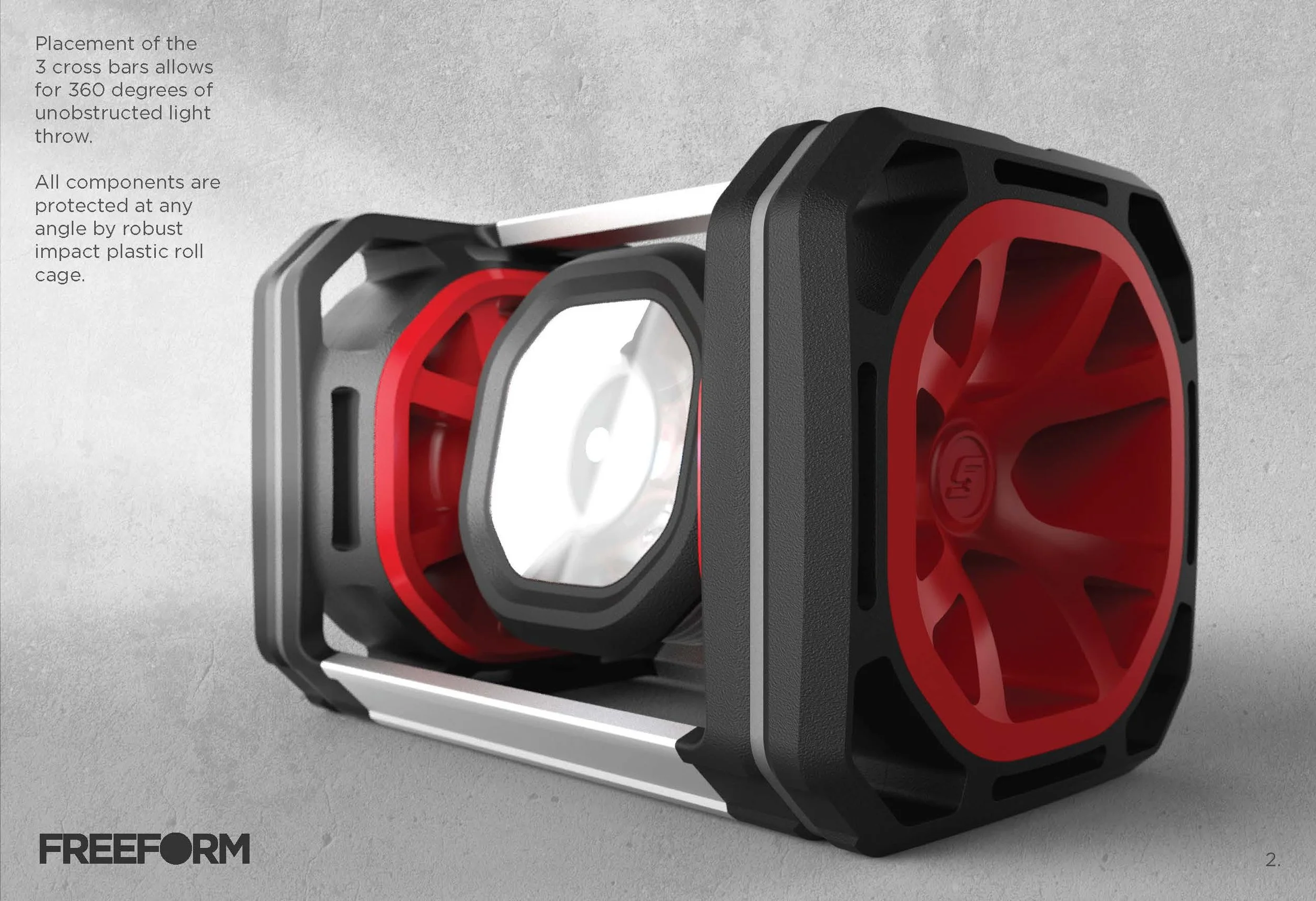

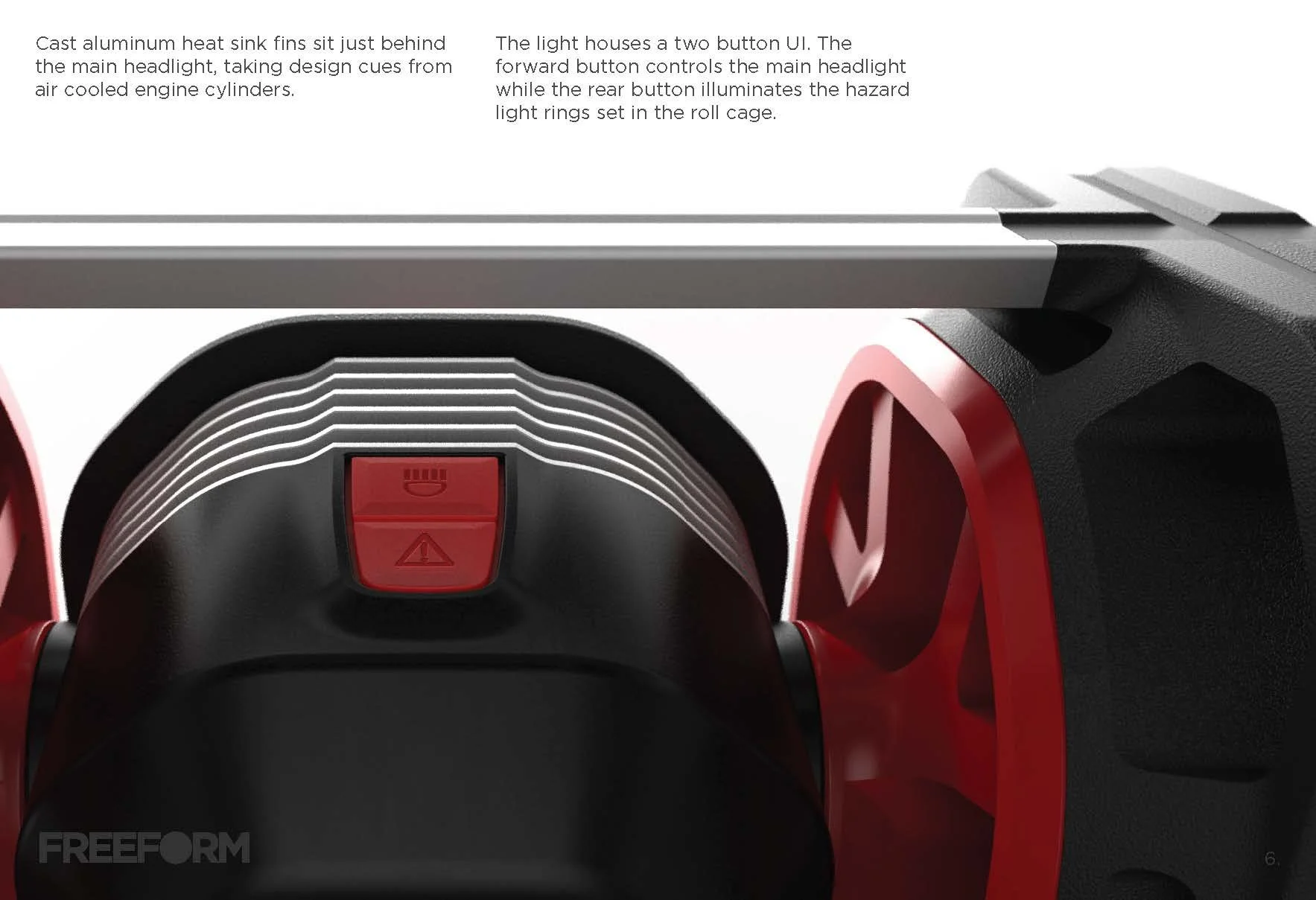

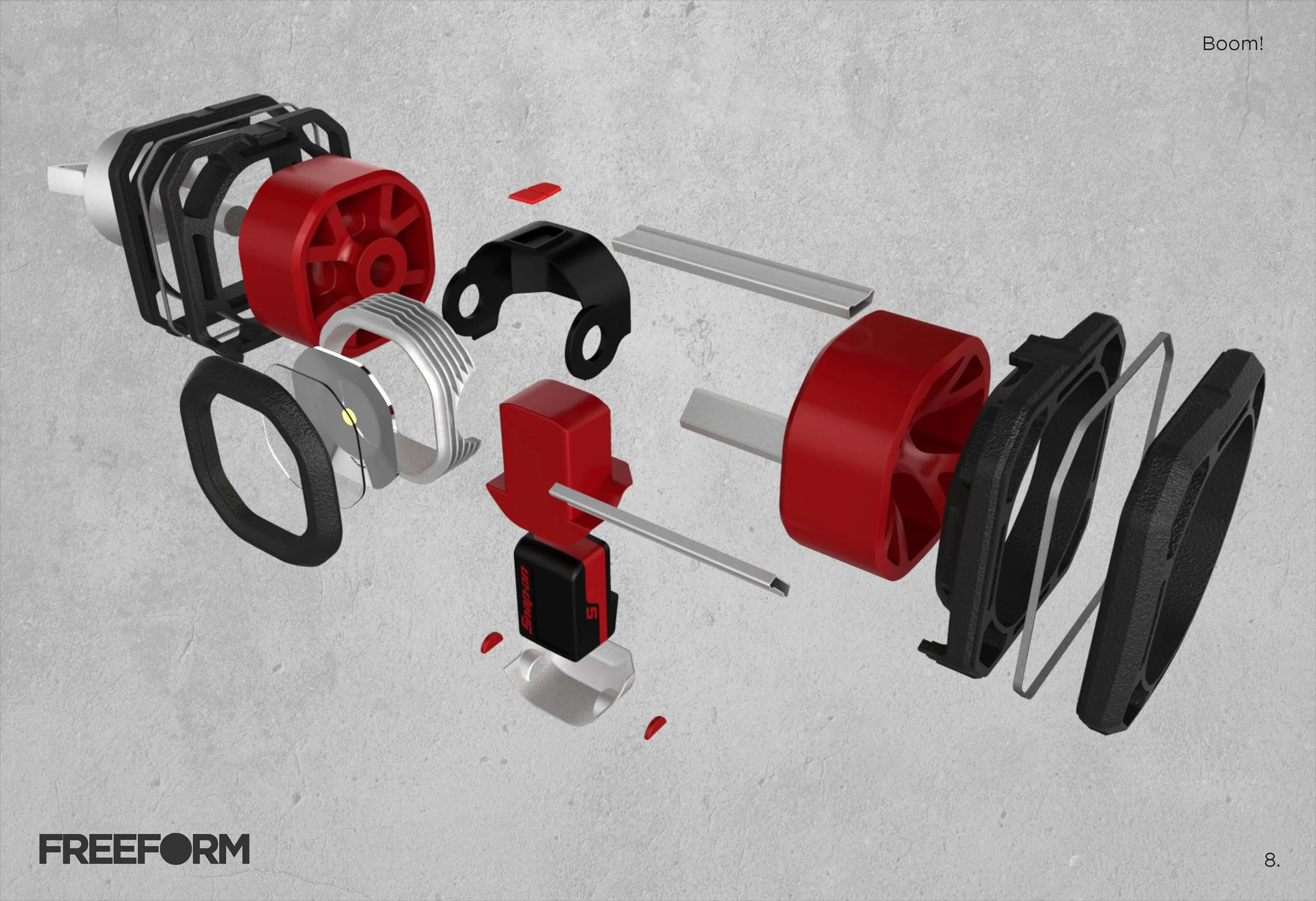

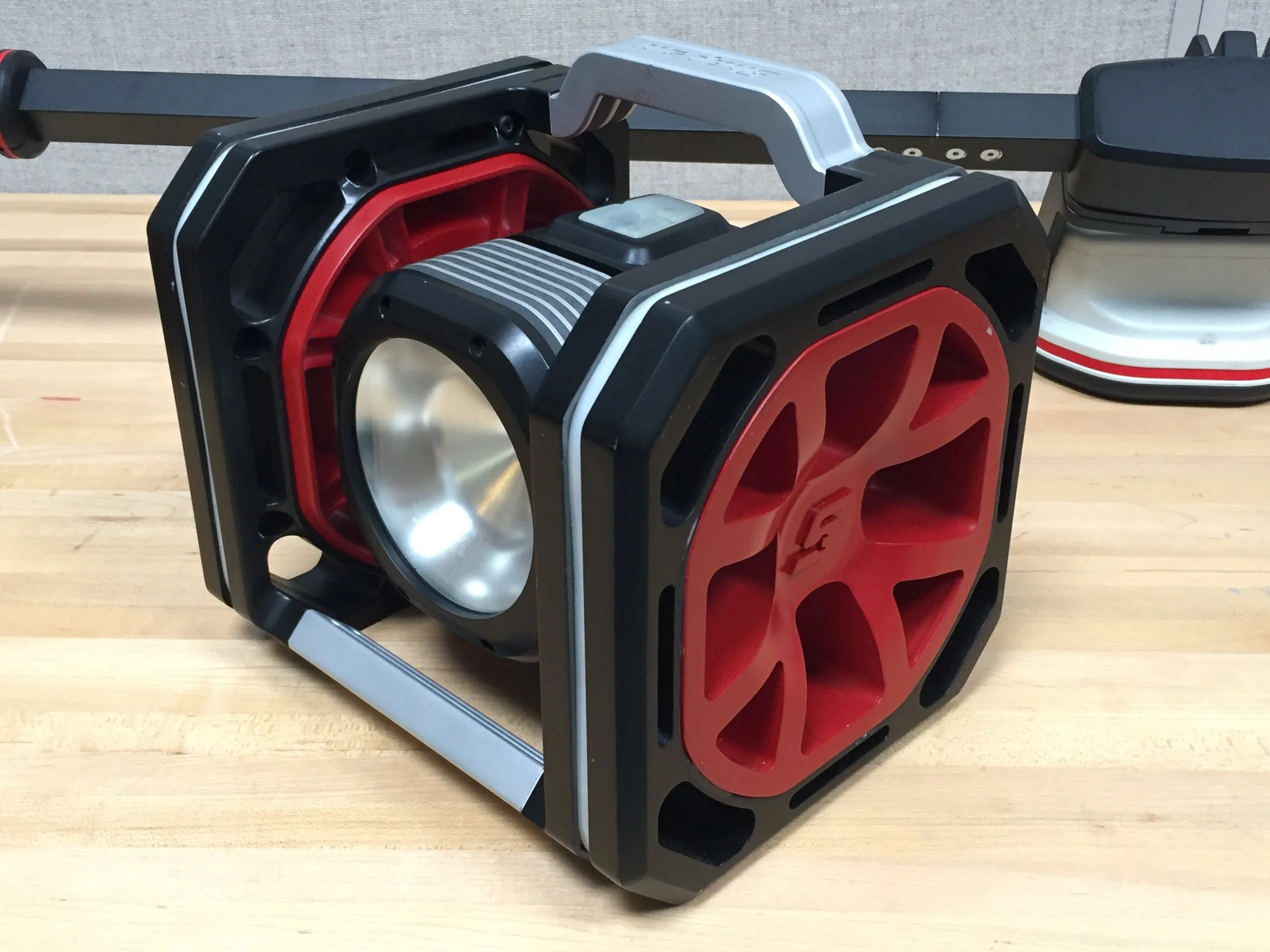

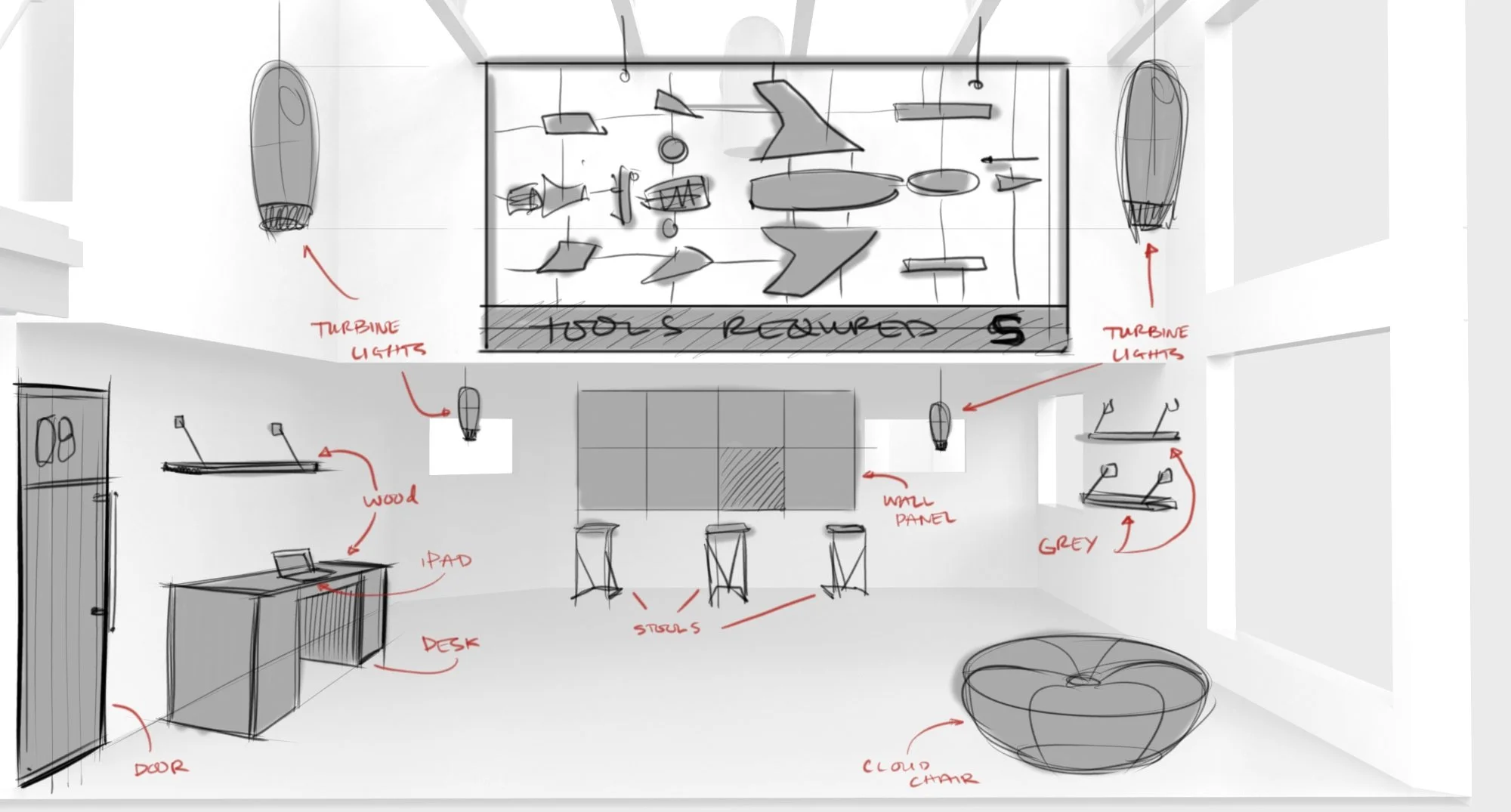

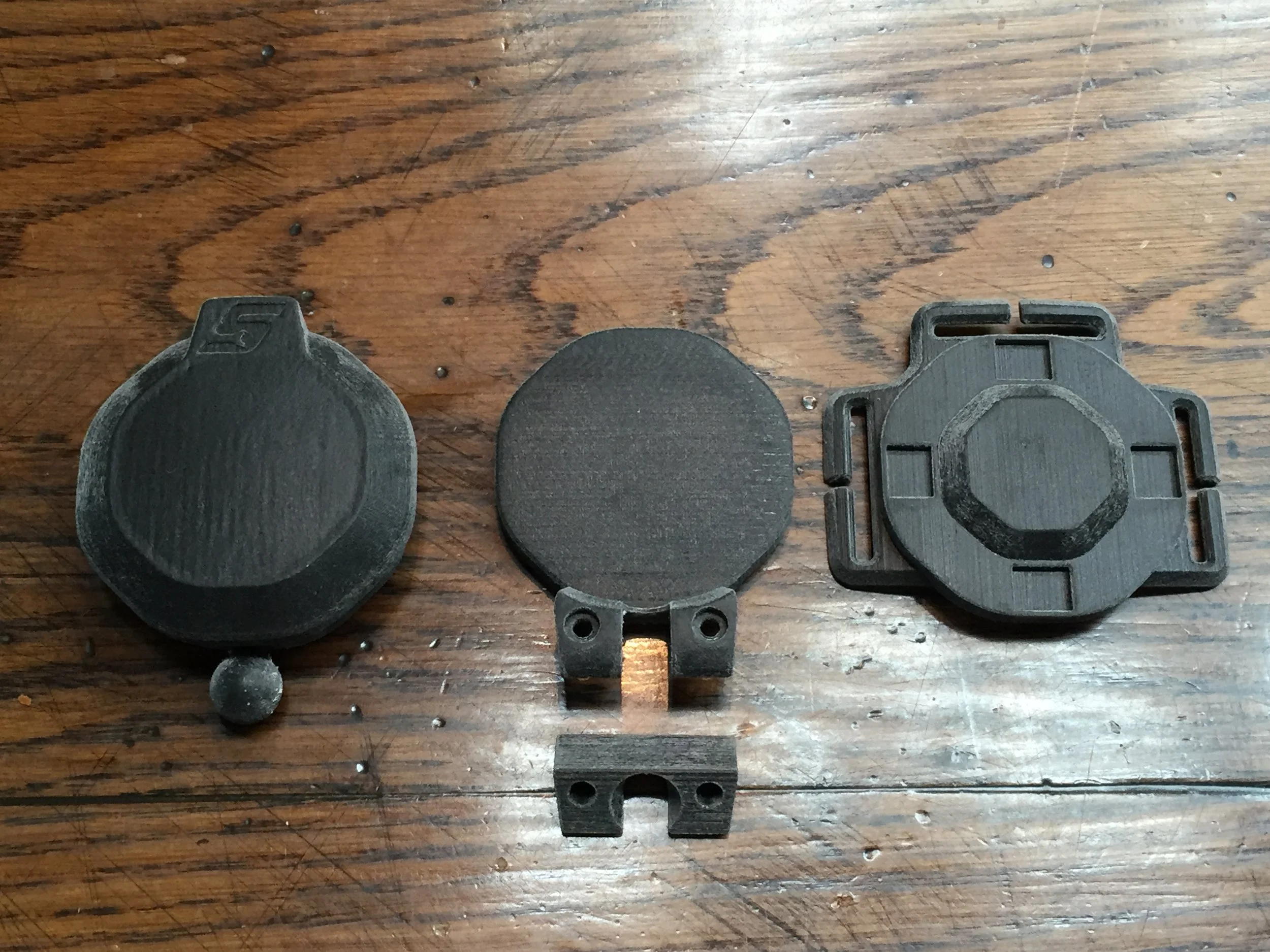

As Lead Designer at Freeform Creative, I managed Midwest clients including Snap-on’s Innovation Department. I helped establish new form language standards that unified a range of professional tools and equipment, developed the first all-in-one mobile alignment machine, and conceptualized brand experiences throughout sponsored technical schools.

In additional to hands-on designwork I was also writing project proposals and conducting new-client outreach.