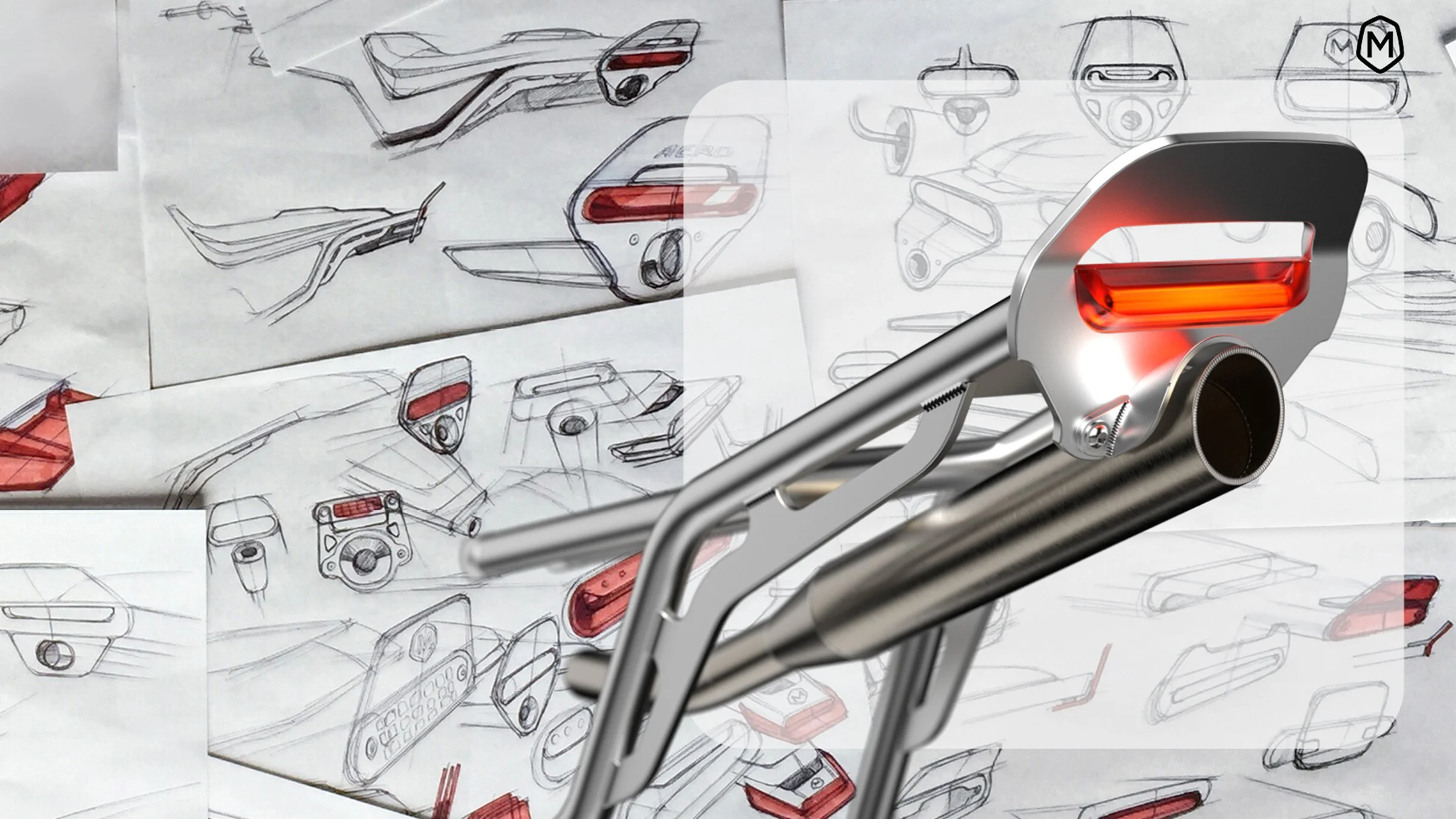

2020

“MM-300” Custom Build

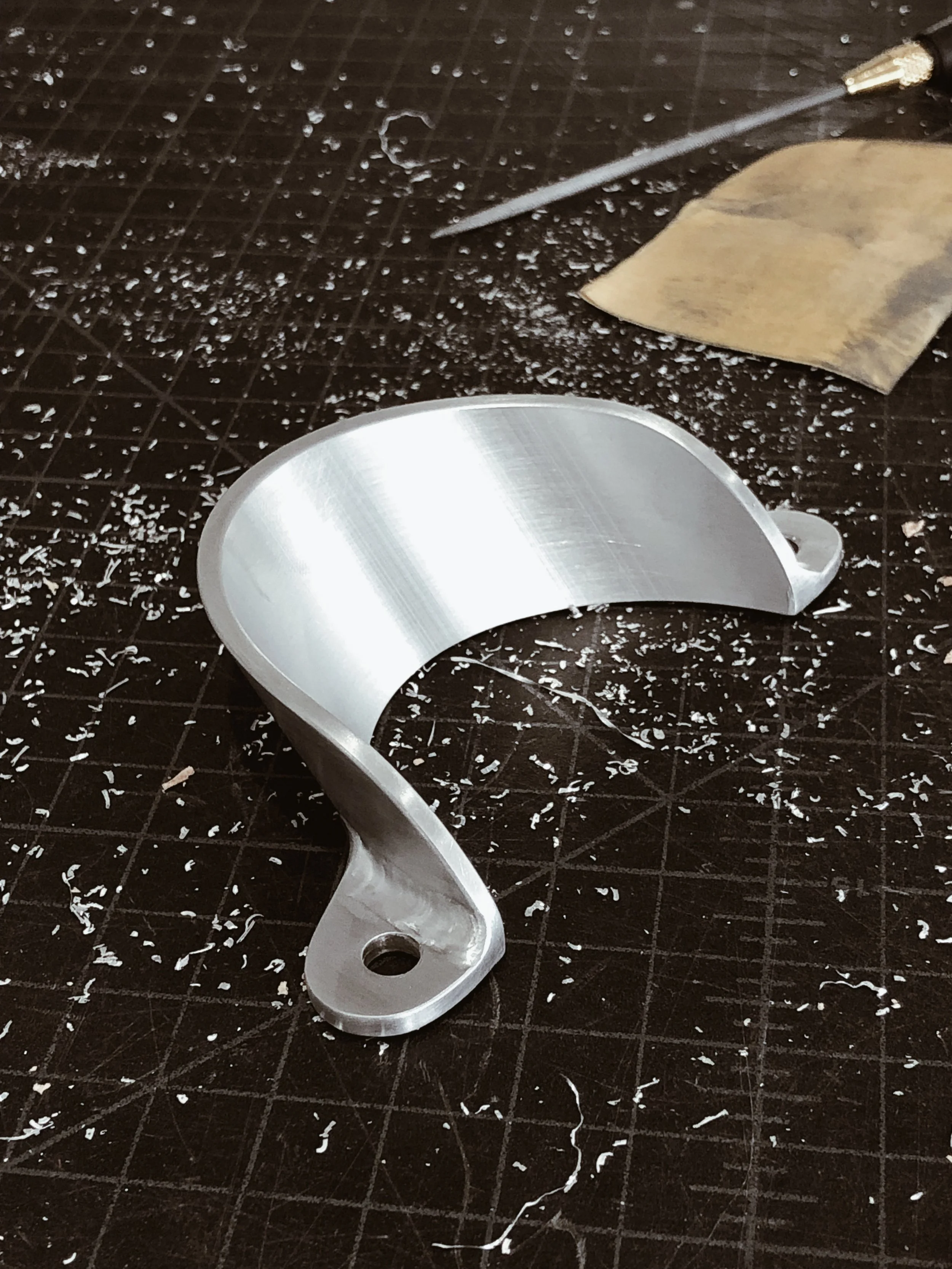

The transformation of a 2014 KTM 300 XC-W Six Days enduro into a sleek, neo-futurist–inspired street tracker with minimalist finishes—combining reworked suspension, 19" dirt-track wheels, and custom hand-formed aluminum bodywork to merge street aesthetics with off-road DNA.

All work outside of upholstery and CNC-machining was completed by myself. This includes:

All up-front designwork

Hand-formed aluminum bodywork

TIG weld-fabricating a new aluminum rear subframe

Seat pan and foam carving

CAD for 3D printed carbon fiber headlight

New electrical harness

TIG welded stainless steel exhaust and muffler

CNC polycarbonate LED tail light with integrated turn signals

CAD for CNC wheel adapter hubs

Final body prep and paint