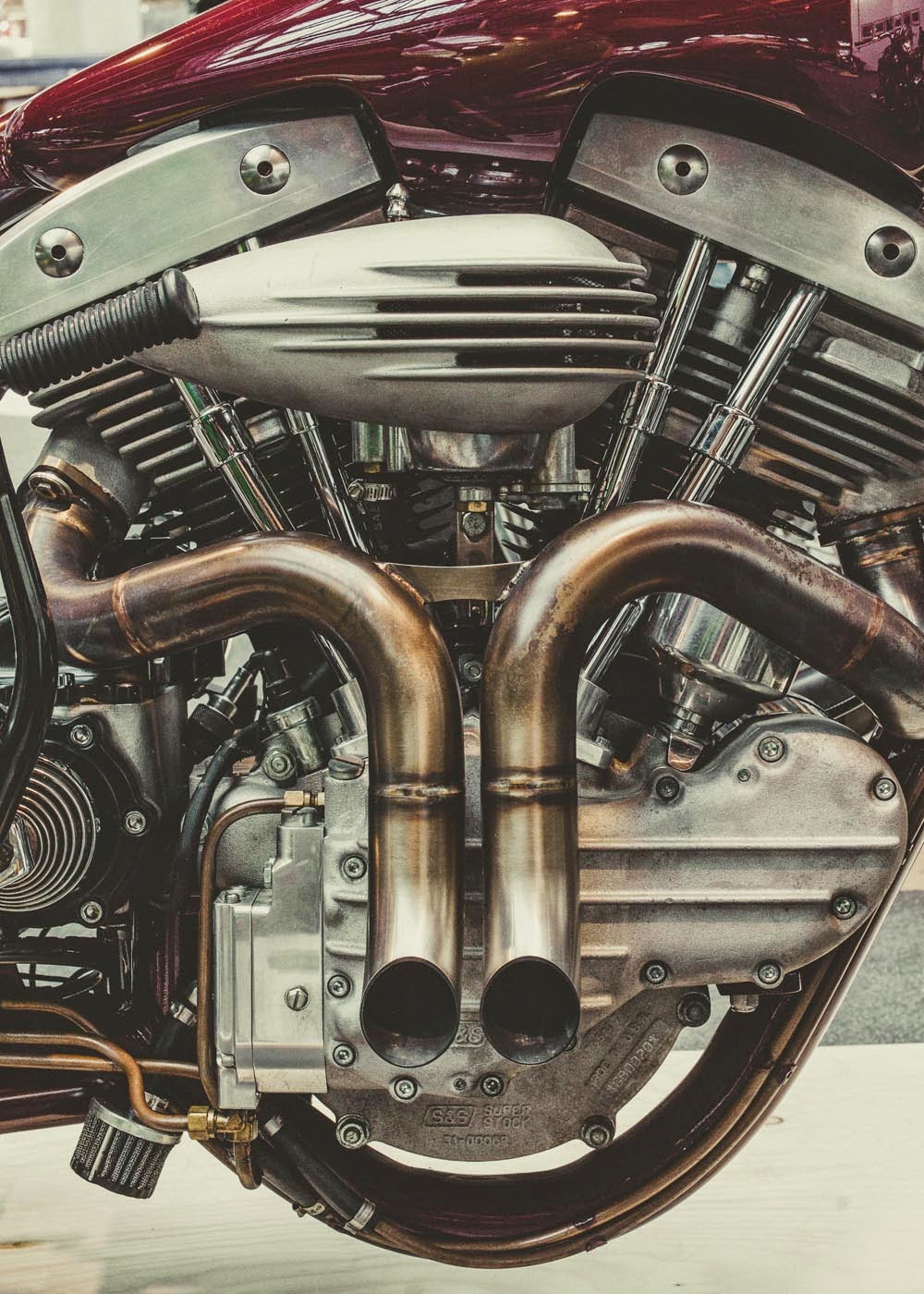

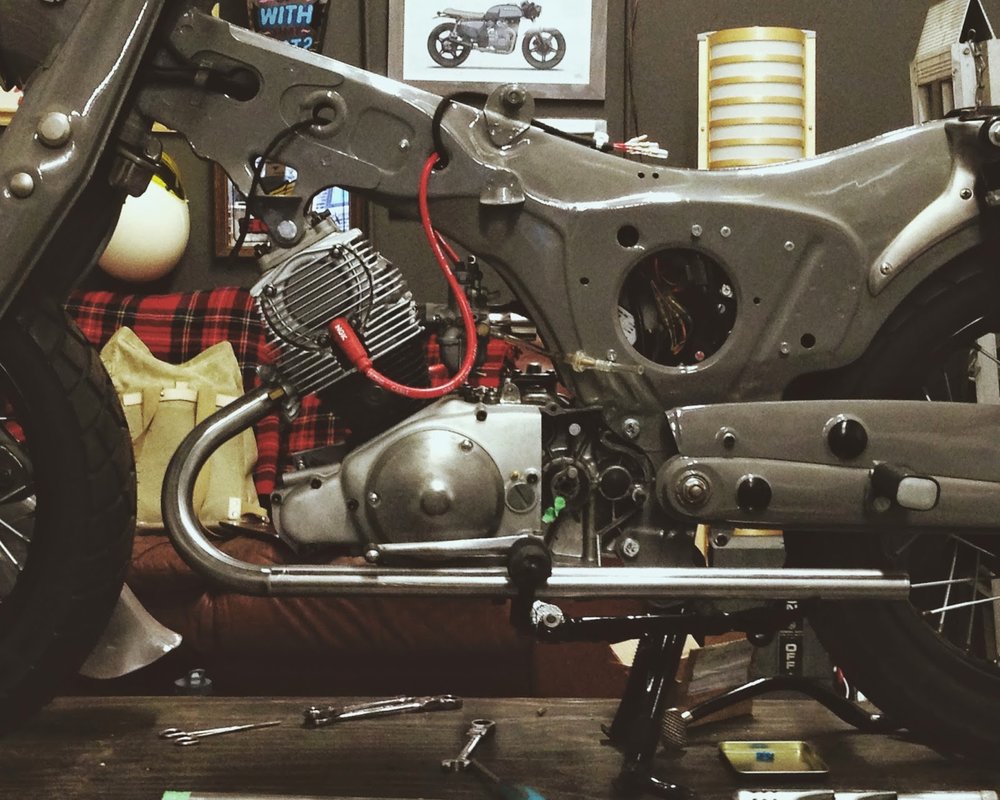

Turns out finding a clean set of headers for one of the first motorcycles Honda brought to the US is nearly impossible. Lucky for me the Honda CA95 exhaust may be the easiest system to replicate. The radii of the bends differ slightly from the left to right cylinder but otherwise they're just one bend then straight back. The only aftermarket systems out there are from Taiwan and are not mandrel bent. This means the pipes have a crushed inner radius and are oval through the bend zone. I bought a set of these to check them out. They were indeed total shit. Here's a quick tutorial on how I made a fresh set.

The first hurdle I had was sourcing the correct mandrel U-bend sections. Pipe bends are measured by their center line radius, or CLR. The pipes on this bike are only 1.25"OD so they're difficult to find especially in specific radii. My stock bend measurements were around 4.00" CLR for the left cylinder and 3.75" CLR for the right. I found U-Bends in the 3.75" measurement at www.mandrel-bends.com but could not find 4" anywhere. So I bought 2 of the 3.75" to see if I could make it work. Which I did. I won't leave you hanging.

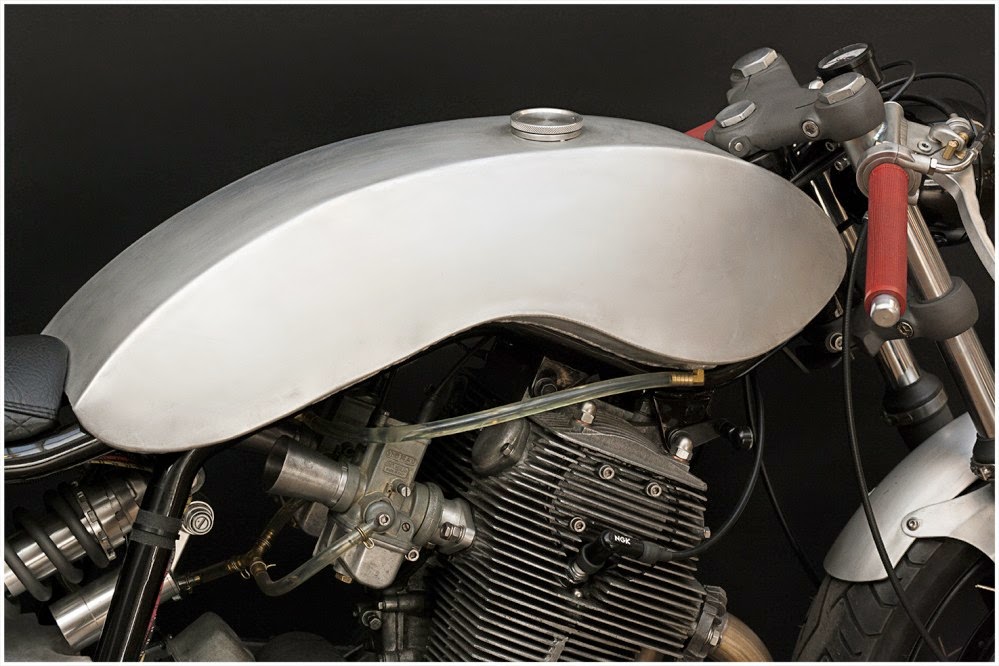

1. Chopped out the bend section of the stock pipes, leaving at least a couple inches of straight on either end.

2. Set up the above jig to map out the angle coming from before and after the radius.

3. Fit the new bend into the jig aligning it against one of it's straight sections. In this case the upper straight. Mark where the lower portion of the bend touches the jig/wood and mark your cut at 90 degrees to the jig.

4. Chop it. Above is showing what the new setup will look like pre-weld.

5. Put the stock pipe with header flange back into the jig and mark where the flange ends (I marked it on the upper piece of wood.)

6. Chop the header fittings from the old pipes (or buy / make new ones if you can. I didn't have anything that could recreate this style flange.)

7. Chop the new pipe down (engine side) per your measurements then tack the old flange onto the new pipe. It's always best to tack weld things together until you're sure everything fits before fully welding. This lets you snap the pieces apart easily should something not line up.

8. I installed the header with tacked on flange to the engine then hovered the straight section in there to make sure the exit angle was correct. I then tacked the straight sections on exactly where I wanted them. Don't forget to match pipe exit height from the rear of the bike.

Here they are all tacked together. I probably used 4 tacks per intersection. You want enough tacks for them to hold their own weight.

9. Time to weld! Make sure you have 3-4 tacks evenly spaced around the pipe before welding. This will prevent the pipes from warping away from eachother due to the heat of welding. Throw them back on afterwards to check your work. If they moved you probably either didn't have enough tacks and/or used too much heat.

10. Time to smooth the welds. You can use a pretty coarse file to knock the welds down flat to begin with then just step to a medium and fine grit. Your goal is to get all the scratches from the previous grit out. Take it slow, it's time consuming. You don't want to dip into the new pipe otherwise you'll create a valley in that area that will be visible after polishing. Always hit it at a 45 degree angle to avoid deeply scoring the pipe with the edge of the file. After hitting it with a fine grit file I bring the pipe to the bench grinder where I go over it with a medium and fine grit metal finishing wheel. They're basically Scotch-Brite pads in wheel form. 3M and Norton make good ones.

That's all for now. I still have some hours of filing and polishing to do to these welds. After that I'll start making some rear brackets and mounting for the bafles.