PROJECT SR250: Fork Assembly and Refresh

/

In the first stage of this fork disassembly write up, I went over some basic refinishing steps, using RustOleum Matte Clear coat to finish the fork tubes. I should note that the most ideal way to protect these fork tubes is clear powdercoat. These are a high wear area and powdercoat will be more resilient then an aerosol finish. However, this build is on a budget and a $10 can of RustOleum fits the bill vs. the $100 or so to get them powdercoated.

Tip: Use brake cleaner to blast out/off all your parts BEFORE you spray the clear coat. Brake cleaner will eat that shit alive and you'll have to sand it down and do it all again. Ask me how I know...

As a general rule of thumb, keep brake cleaner away from all paint / powdercoat. You'll also want to use a prep-sol / mineral spirits to clean the bodies off after brake clean and before clear coat. Any oil or debris is going to mess with your finish, and brake clean can leave residue.

It's important to note that reassembling SR250 forks is NOT a fun one person job. 3-4 hands are required at times - namely when attempting to hold the fork shaft and pushing the plug down enough against the force of the spring while trying to insert the circlip retainer. Came pretty close to launching that solid metal plug straight into my face a few times. Make friends with hands.

Sealed up and ready to go. Yamaha calls for 10w30, but Belray 20w fork oil is good stuff as well.

PROJECT SR250: Fork Disassembly & Refresh

/

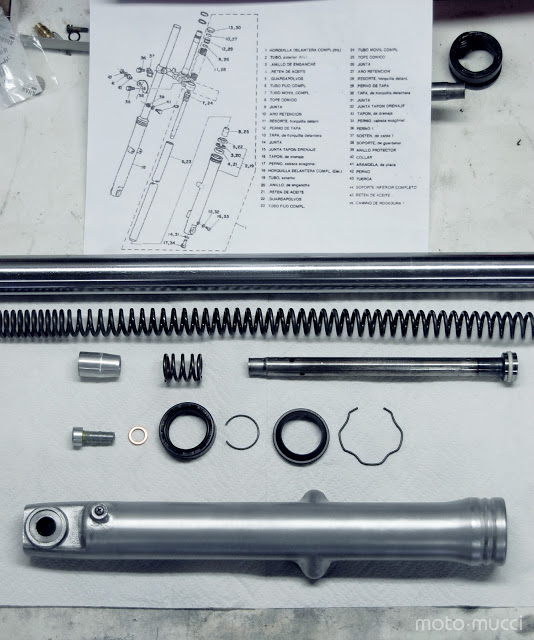

In between a handful of other projects for the SR250, I've been tearing down and refreshing the forks.

Getting them fully dissembled proved to be a difficult task, as there just isn't much information out there for this bike.

After gutting the piston of it's cap spring retainers etc, the next step is to remove the piston shaft itself.

This is where I got hung up, so here's how to do it:

1. There's an allen bolt at the base of the fork body. Get an allen key on that.

2. Down inside the piston shaft there's a female 12pt bolt head - size 14mm. This is what the allen bolt is threaded into. Loosening only the allen bolt at the base of the fork will usually result in this interior piece just spinning, so you're going to need to get a 14mm allen key on that piece also.

The expensive way to do this: H14 allen key socket on a 12"+ extension

The cheap way to do this: Weld or screw on a 14mm nut to the end of a threaded rod. With the screw method you'll need 2 nuts to lock them. Bend the other end into a handle.

Here's what that interior piece looks like, with a H14 allen socket in it:

After I finally was able to fully dissemble both forks I started refinishing the bodies.

Before and after:

Process:

1. Wire brush wheel drill attachment to remove clear coat, corrosion and gunky crap. Keep your direction consistent.

2. 180 grit sandpaper for brushed look

3. Clean with mineral spirits / prep solvent

4. Finish with RustOleum matte clear coat

I'll get more pictures up with they're completed.

DAILY INSPIRATION: Adam Forrester's '79 CX500

/

1979 CX500

Here's a good example of what just a handful of the right modifications can do for a bike's appearance. The bike is an in-progress build right now. Adam says they are still looking to put some new tires and shocks on, along with getting some more items powdercoated.

The List

- Refashioned and Reupholstered Stock Seat

- Powder-Coated Exhaust, Roll Bars, Tank, and Handle Bars

- 7” Headlight, Turn Signals, and Rear Brake Light from Dime City Cycles

- Custom Rear Bracket for Tag, Brake Light and Turn Signals

- 2.5” Gauges from Dime City Cycles

ART&DESIGN: Steel Toe Press and the Chicago Motorcycle Culture

/

Back in 2005, Larry Fletcher founded the Ton-Up Chicago chapter, along with an events coordinating company called Steel Toe Press. Steel Toe Press is behind all the major motorcycle events in the city, and is responsible for Chicago's flourishing motorcycle culture. If you've ever lived in a place where there are plenty of motorcycles and no gatherings, that's because there's no one like Steel Toe Press planning all your events, scheduling bi-weekly meet ups, booking bands and venues, and getting the word out to the community.

Larry's partner, Martin Cimek is the man behind getting the word out. Martin runs an illustration and graphic design company, called MCD, and is responsible for all the event posters and art work for Steel Toe Press.

Here are some of the posters from past Mods vs. Rockers events.

All posters are silk screened, 18x24" prints, and are available at www.MvRGear.com

$50