PROJECT SR: In Full Swing

/

With the CX's recent engine out repair,

Project SR had to take a back seat. Now that the CX is back up and

running, the SR build is in full swing. I spent the better half of a day

putting together a spreadsheet of deadlines that would need to be hit

in order to get the bike done by the Chicago Mods vs. Rockers meet, June 15th - 16th. It's going to be VERY tight. Challenge accepted.

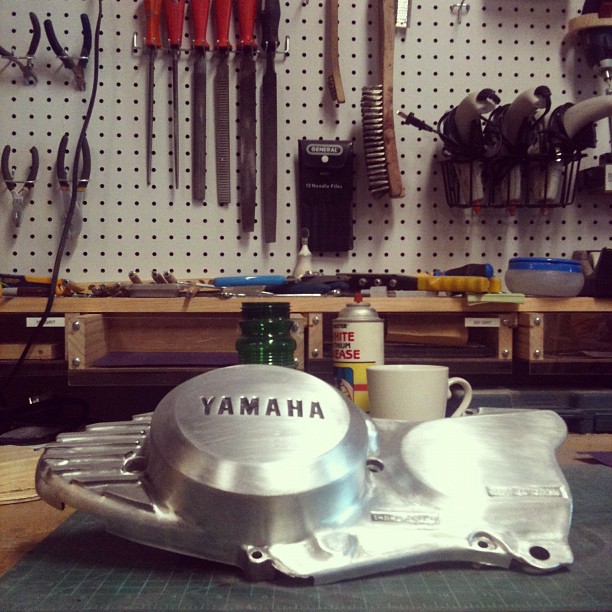

I got around to finishing up the left side casing this past weekend. I'll usually hit them with a wire brush attachment on a drill first then go on to sand paper. This one I took up to 180 grit and I think I prefer it to the 120 on the right side casing. I'm planning on hitting the right side with 180 next.

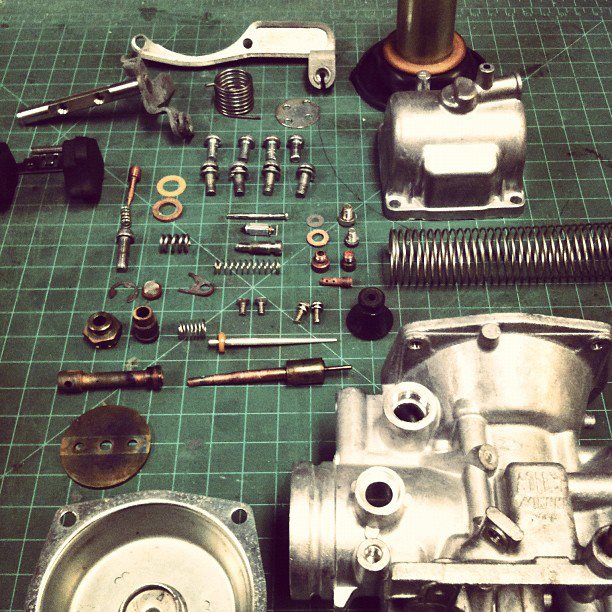

The SR's Mikuni B34 carb dissembled. Quite a lot of parts for a single cylinder.

All cleaned up and ready to go back together.

The frame has now been shaved of all it's excess tabs. Tomorrow I'll be working on fabbing up some new mounting points for the Honda tank to sit on. This was the first time I've used a "flap disc" and I'm now of the opinion there is no better way to smooth out metal burs. It allows you to get a much more consistent finish then trying to smooth with a grinding disc, and risking taking off too much material.

In my spare time I've been separating out and stripping all the parts that will be going to powder coating, painting, and plating. Aircraft Stripper does the trick.

The parts keep rolling in and I'm trying to stay as efficient as possible, juggling many different projects at once. The timeline I created helps immensely. It can take a while to work out but it's a great guide to keeping yourself on track.

FEATURE: Micah's Stretched 1974 Honda CB360

/

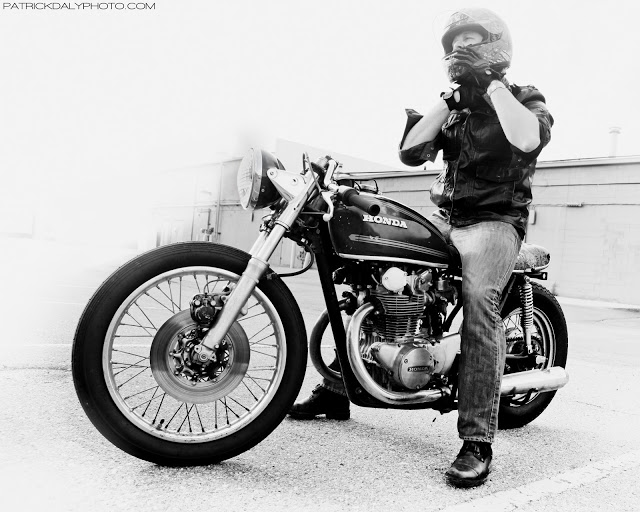

I teased about this bike a little while back, and for those of you who e-mailed me wondering where the rest of it was, behold:

1974 CB360

Detroit, MI

Photographed by Patrick Daly

I met Micah a while back, in my college days at Detroit. We were both into Volkswagens at the time and got to talking shop. Micah has been a VW head since he was able to drive, having owned and modified 5 to date. "I'd always been intrigued by motorcycles, but never thought I'd own one." A lonely 1974 CB360 sitting in a friend's shed would change all that.

"I saw the bike and asked him

how much it would cost for me to take it home with me. He half-jokingly said $300, and I, not so

jokingly said, "deal! " I

couldn't pass it up..."

Micah was raised in the northern suburbs of Detroit. He previously worked at a metal fab shop for 3 years, where he learned many trades. He currently works as a facilities and maintenance tech at the College for Creative studies in Detroit, and has been doing so for the past 3 years.

"I couldn't have done this project without our [CCS] shop,

and all the equipment we have there."

"Most of the fab work went on in the facilities

shop at CCS, where I work during the day. I'd stay late at night, or come in on

the weekends, and do some welding and grinding. We have a sandblaster that

could fit a love seat, which allowed me to blast my frame and wheels before

paint.

The motor was re-ringed, received

new gaskets, and was reassembled in a hotel room. Haha, my buddy Jeff Schmidt

was in town from Brooklyn. He has rebuilt many an old Honda motor, so we

decided to do all the work down at the Double Tree hotel on Lafayette in Detroit.

I'll never forget the look on

the woman's face at the front desk when we rolled an assembled motorcycle

engine out on the luggage cart.

The final assembly of the bike, and

making of the wiring harness, happened in my living room. It was February, and I don't have heat in my garage, so I decided to do it inside. Thankfully I have

awesome roommates who are understanding. It was really a nice way to do it, actually. When it was done, we just rolled it down the

front steps, and away I went."

Micah's inspiration for the seat came from the aesthetic of weathered Brooks saddles. He set out to build one by hand, first mocking it up with a piece of Masonite. Using a plasma cutter, he traced the shape in steel and sent it through a roller until he was happy with the contour. I've personally sat in this seat and can attest to the butt-hugging perfection and comfort you wouldn't expect from it's minimal appearance.

"A buddy of mine cut me a piece of the thickest

cow ass he had, and I used copper rivets to attach it to the seat pan."

Putting to use all those years of fabrication training, Micah set out to build some custom bars using chopped off stock handles and the clamps from a donor lower triple tree. He also extended the swing arm out an additional 5in. The new length required him to extend the drum brake holder and actuator rod, and swap the rear suspension out for some stiffer units off a CB550. The WWII first aid box houses his battery and the stock ignition was mounted to the side.

Would you ever sell it?

"I've asked myself that, and to be honest I'm not

sure I know. On one hand, I think if someone came along and was interested

enough to offer me something outrageous for it, I would. On the other hand, it's my first bike,

and my first build, so it would be kind of cool to hang on to it for awhile."

Feel like offering Micah something outrageous for it? Hit the link at the top of this article to get in touch with him. Or instead, maybe just hold out for the '72 CB550 he's wrenching away at currently.

Feel like offering Micah something outrageous for it? Hit the link at the top of this article to get in touch with him. Or instead, maybe just hold out for the '72 CB550 he's wrenching away at currently.

FREE CABIN PORN FRIDAY: Head for the Hills!

/

Remote cabin on the Norwegian Island of Vannoya.

Photographed Jack Hobhouse.

How to Head For The Hills on a whim!