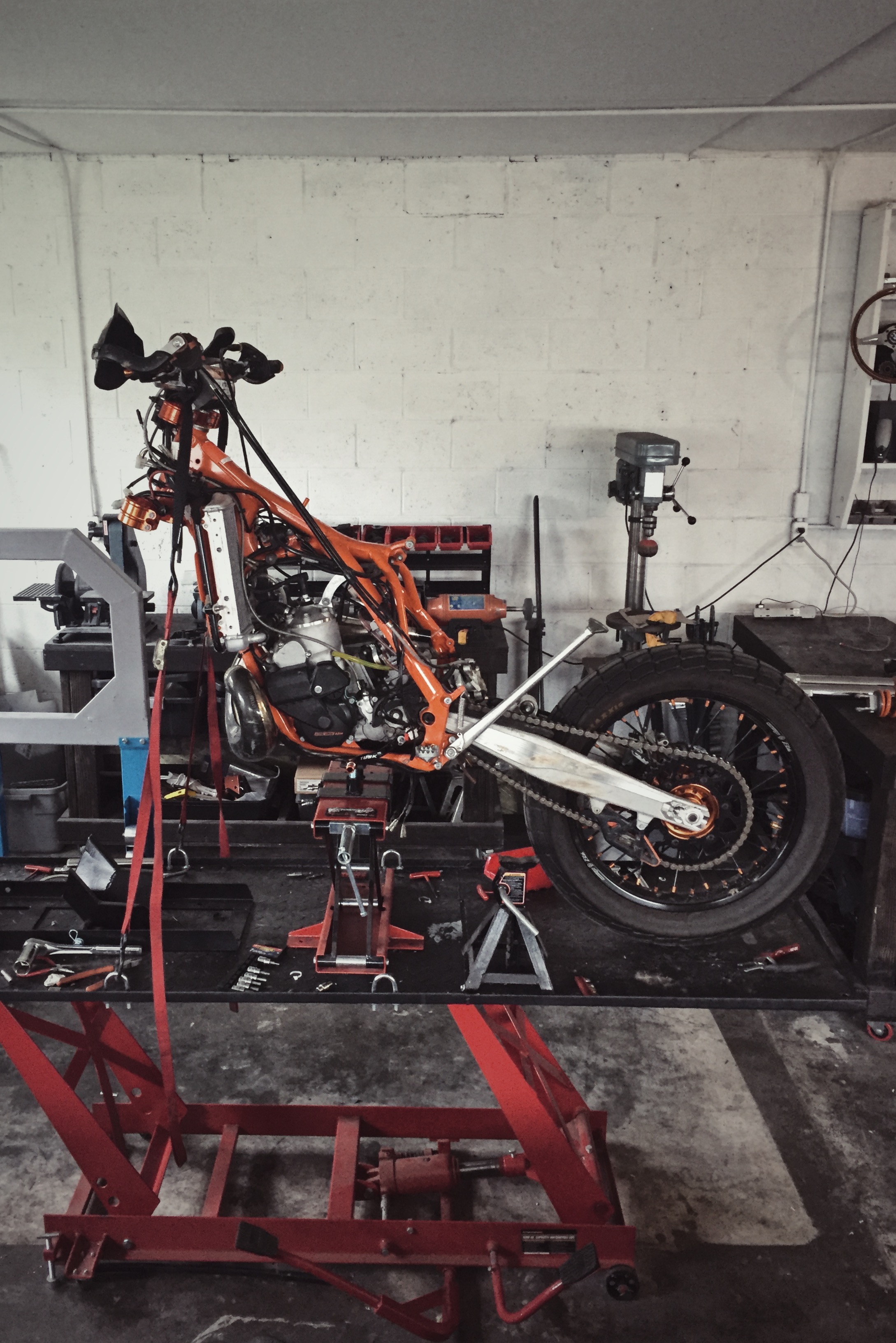

KTM 300 BUILD: The Kick Off

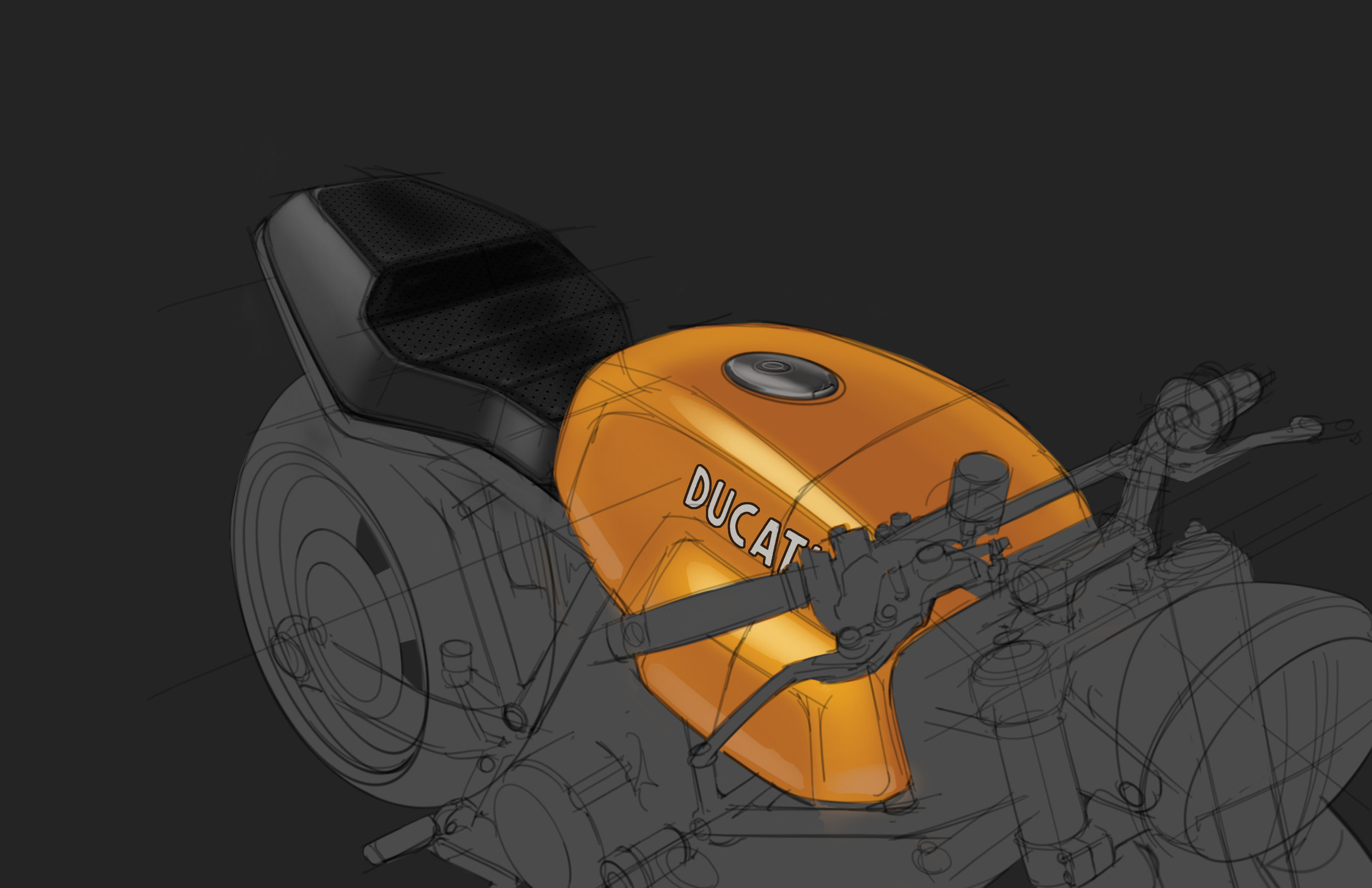

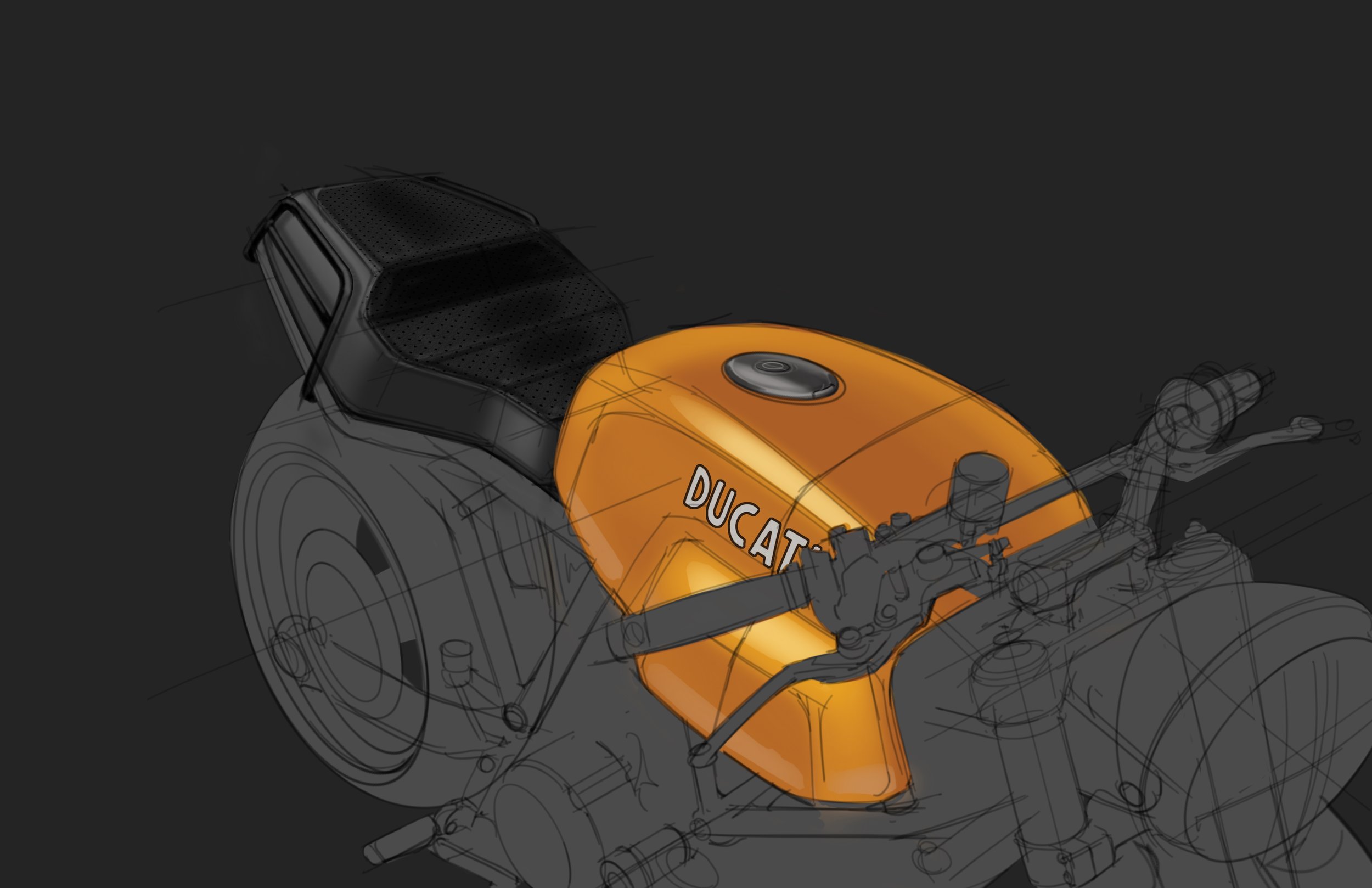

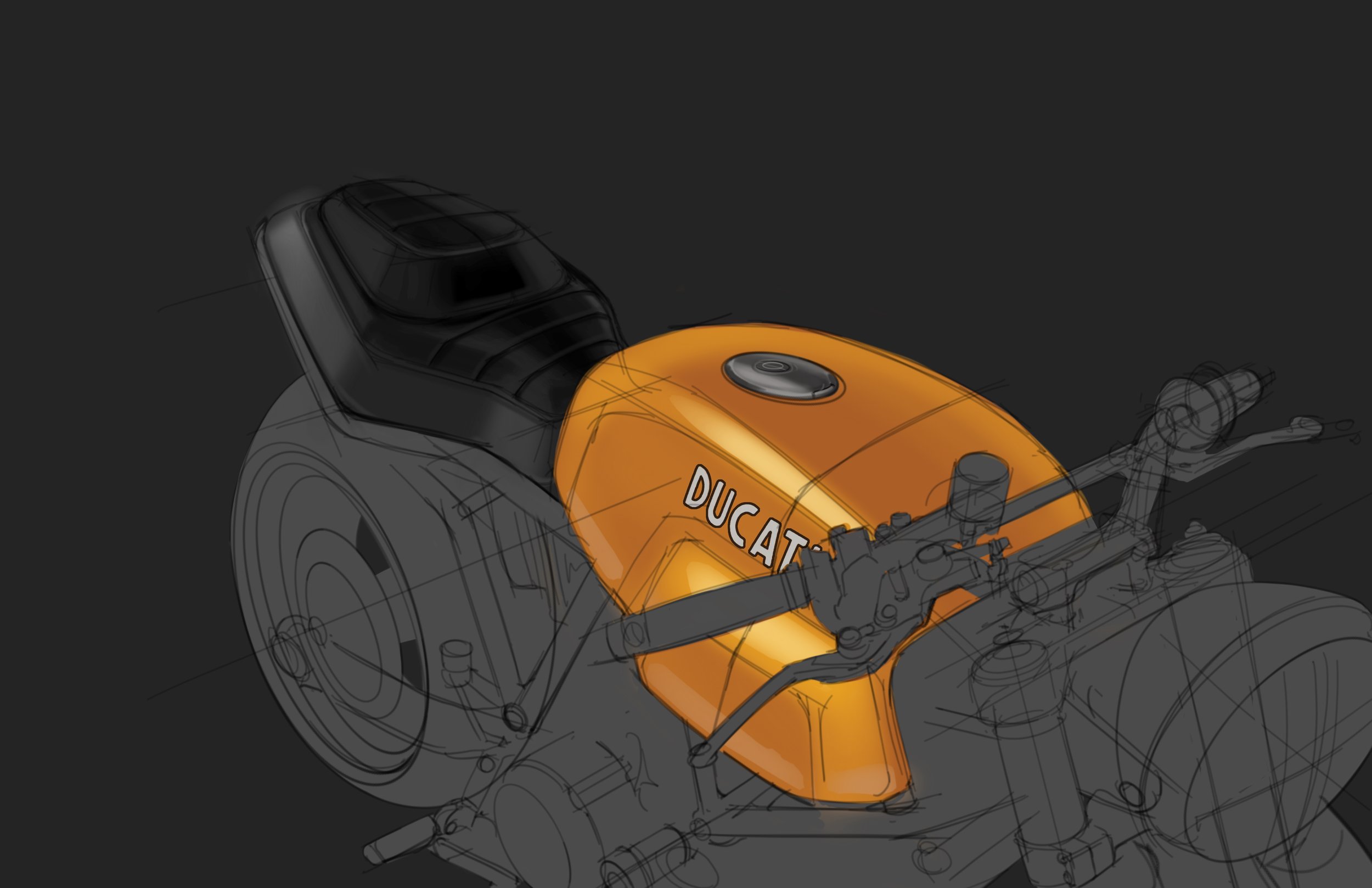

/Here's the new long term build project: a 2014 KTM 300 XC-W Six Days model. The owner has a lot of other purpose built dirt bikes so he's looking to turn this one into a street tracker. Purists may want to skip over this one as I'll be stripping everything Six Days related off this bike and custom making most of their replacements.

The strip down process begins. Everything goes into labeled boxes and baggies for future reference. As a street bike we won't need the 14" of travel so the WP suspension came off to get rebuilt. 2 inches was taken out of the travel and stiffer springs and valving were fitted. The fork tubes were anodized and rear shock was painted satin black.

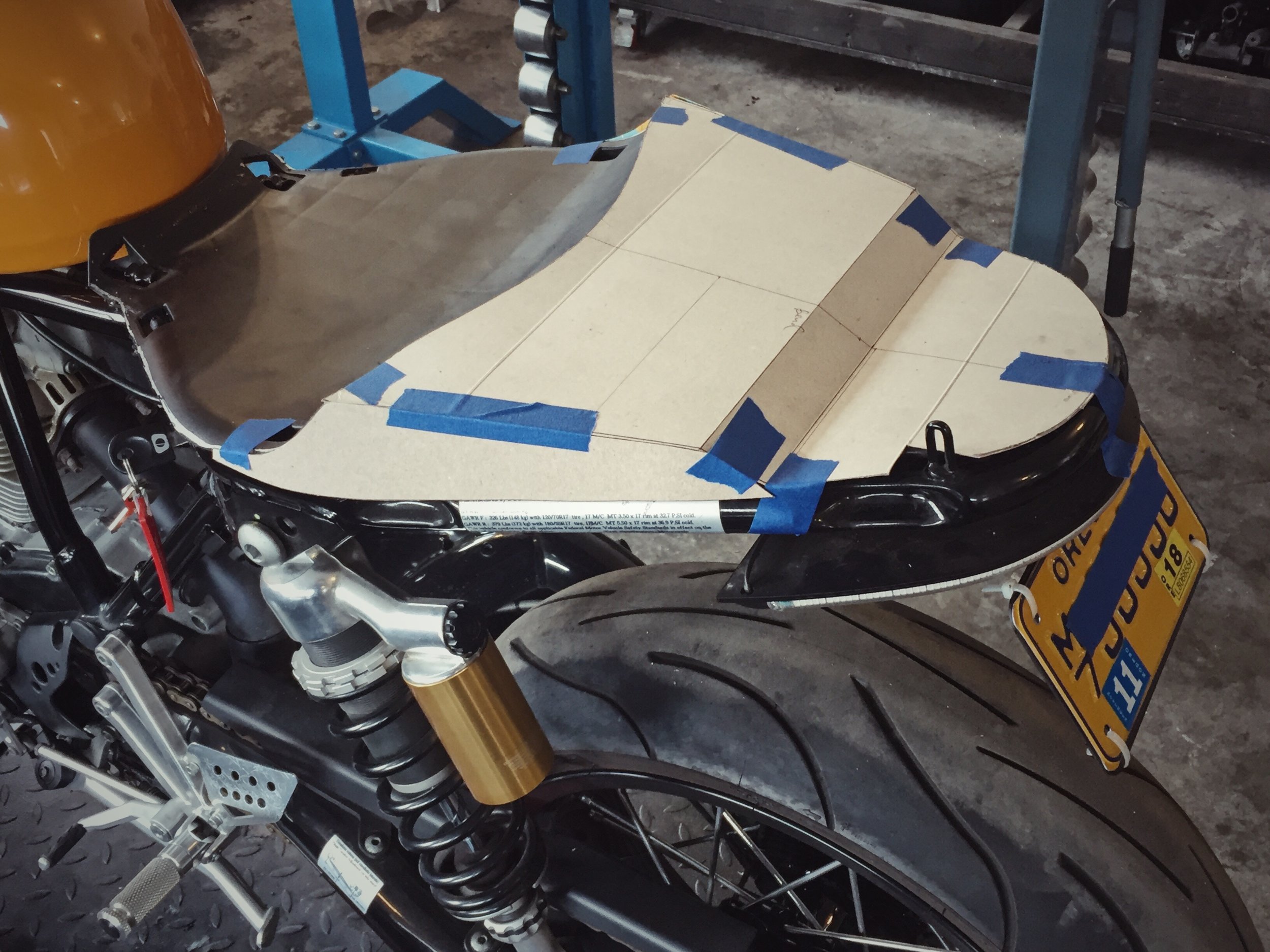

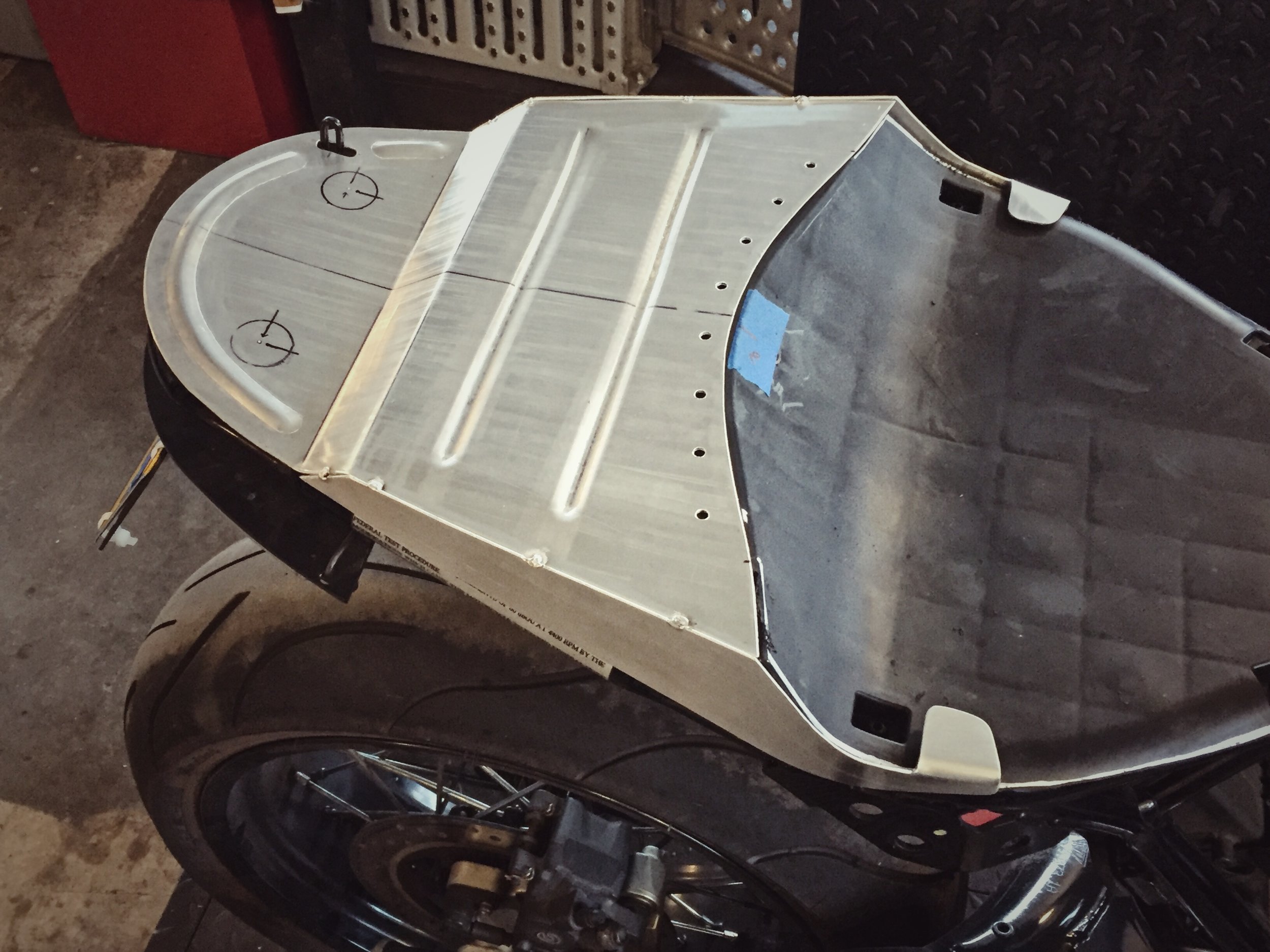

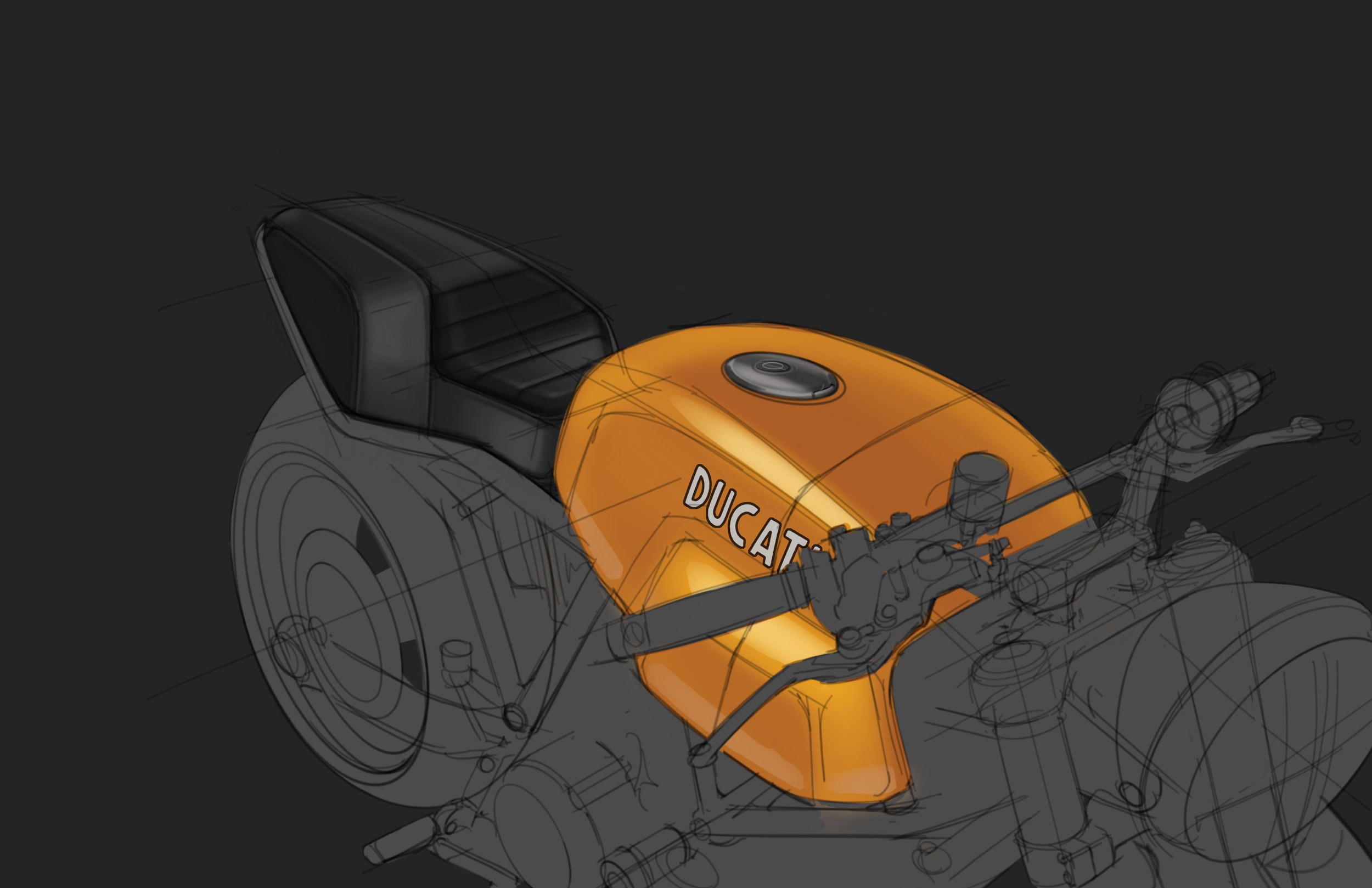

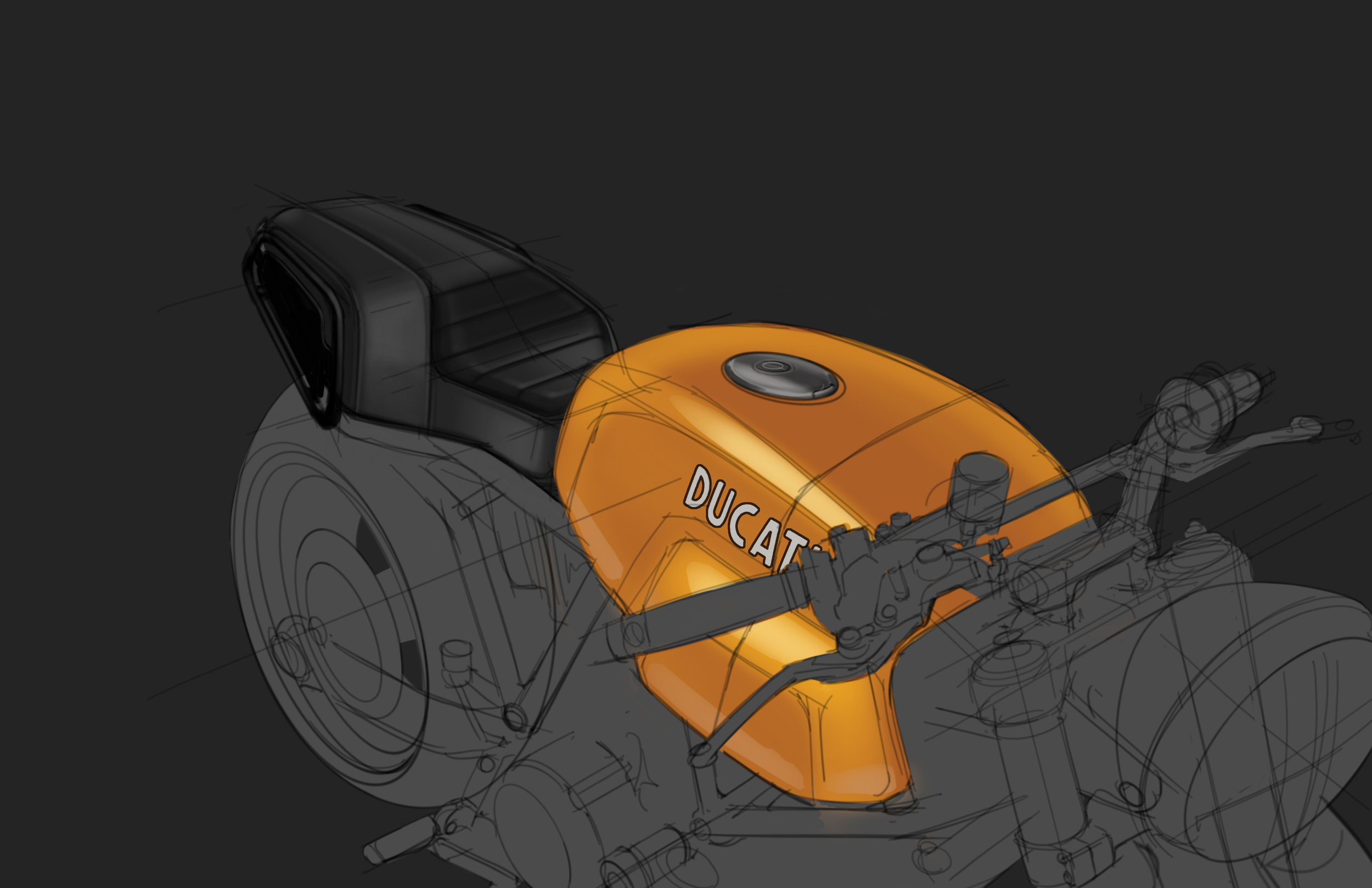

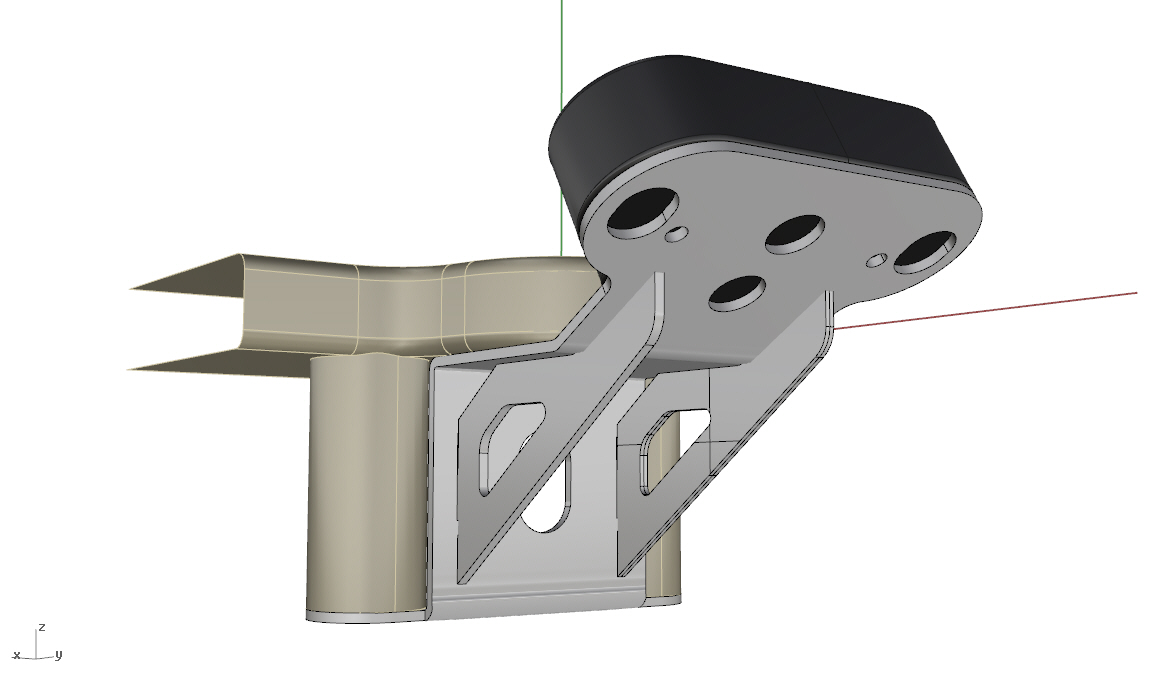

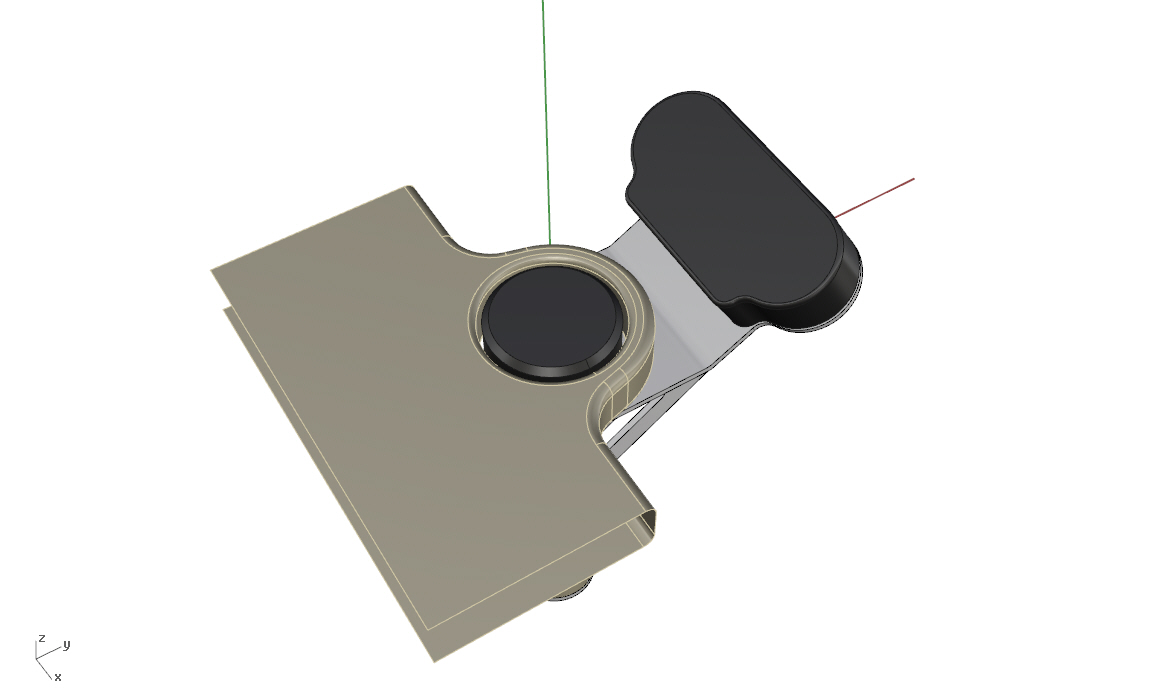

Above is the new street ride height. With that set now I can start plotting out the subframe. To keep the weight down the subframe will be made out of 6061 aluminum just like the stock unit. The uprights have complex curvature to them so it took a few tries to get everything to hit the right points.