PROJECT SR250: Fabricating an Electronics Box

/

Once a week I take a welding class at a local tech school. This semester just kicked off and I'm trying my hand at TIG. I've only used the machine twice so far but oh man is it amazing. The amount of control you have is great and you have the ability to go back over crappy welds, melt them back down and reform them. Something I couldn't do with the mig.

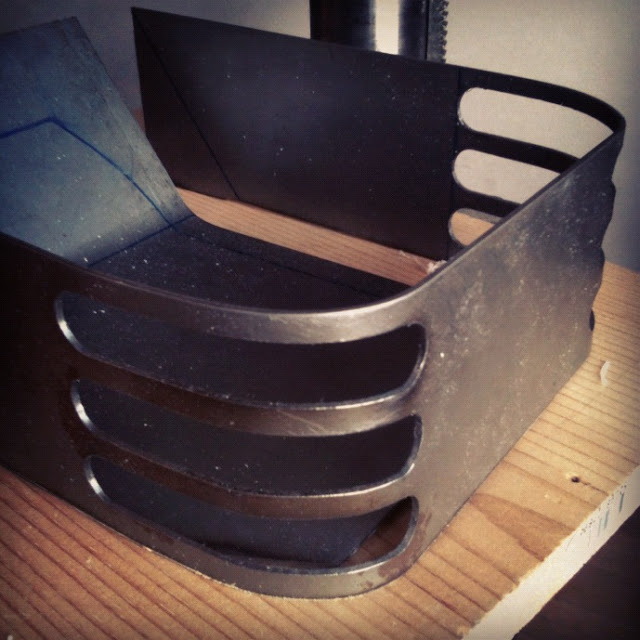

The first project I took on was a battery/electronics box for the SR250. The box is out of 16g steel. I used the mill to make some vent details and worked the sheet around some steel pipe for the bends.

I had the TIG machine set up to 105 amps. After talking with some people it seems like I had the amperage a bit high, and the HAZ (heat affeected zone - blue area) is telling of that. All of this I just learned about. I'm told I should dial the amperage back, take my time, and aim for about a 3/4" HAZ.

Here's the result:

If you've got any other tips and tricks, as always I'd love to hear them.