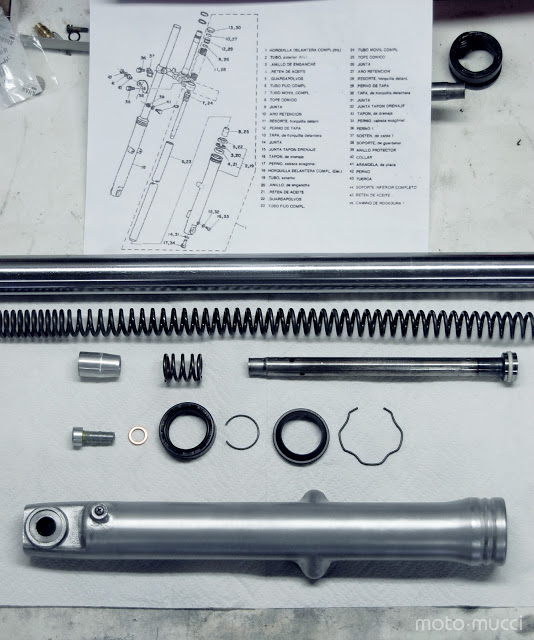

PROJECT SR250: Fork Assembly and Refresh

/

In the first stage of this fork disassembly write up, I went over some basic refinishing steps, using RustOleum Matte Clear coat to finish the fork tubes. I should note that the most ideal way to protect these fork tubes is clear powdercoat. These are a high wear area and powdercoat will be more resilient then an aerosol finish. However, this build is on a budget and a $10 can of RustOleum fits the bill vs. the $100 or so to get them powdercoated.

Tip: Use brake cleaner to blast out/off all your parts BEFORE you spray the clear coat. Brake cleaner will eat that shit alive and you'll have to sand it down and do it all again. Ask me how I know...

As a general rule of thumb, keep brake cleaner away from all paint / powdercoat. You'll also want to use a prep-sol / mineral spirits to clean the bodies off after brake clean and before clear coat. Any oil or debris is going to mess with your finish, and brake clean can leave residue.

It's important to note that reassembling SR250 forks is NOT a fun one person job. 3-4 hands are required at times - namely when attempting to hold the fork shaft and pushing the plug down enough against the force of the spring while trying to insert the circlip retainer. Came pretty close to launching that solid metal plug straight into my face a few times. Make friends with hands.

Sealed up and ready to go. Yamaha calls for 10w30, but Belray 20w fork oil is good stuff as well.